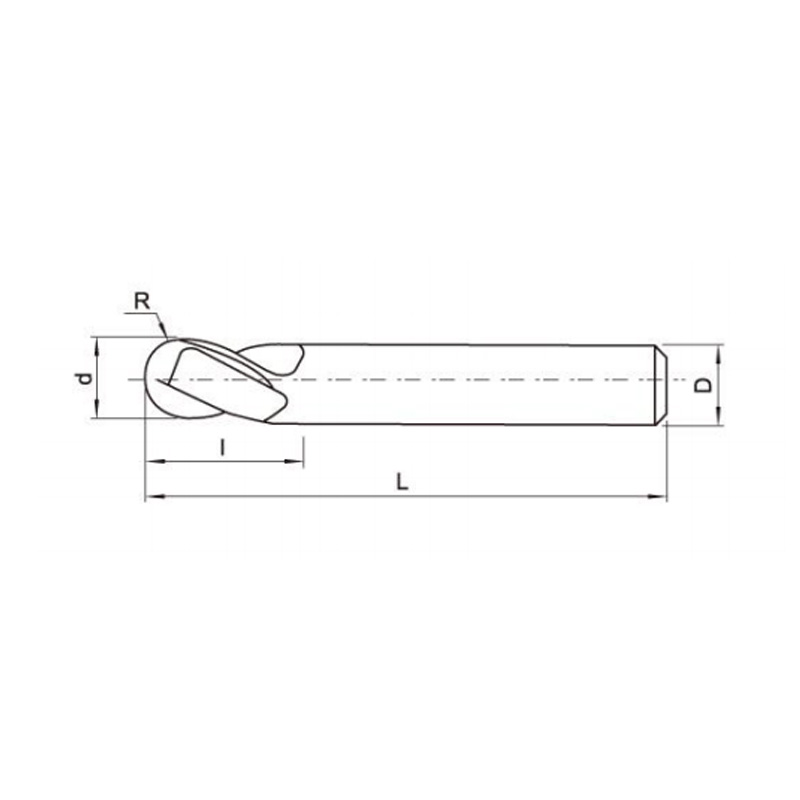

Product Specifications

The differences between the series of 2-flute ball end mills at HRC45, HRC55, and HRC65 lie primarily in their hardness and the range of materials they are suitable for.

1. HRC45: This type of end mill has a hardness of HRC45, which is relatively soft. It is suitable for machining materials with lower hardness, such as some plastics, aluminum alloys, and common carbon steels. Due to its lower hardness, it typically cannot handle the machining needs of high-hardness materials, but it performs well on materials within its range of applicability.

2. HRC55: End mills at this level have a hardness of HRC55, which is slightly harder than HRC45. They are suitable for machining materials with slightly higher hardness, such as some stainless steels, alloy steels, etc. Compared to HRC45, they have improved cutting performance and wear resistance, which can increase machining efficiency and tool life to a certain extent.

3. HRC65: End mills at HRC65 have higher hardness and are suitable for machining high-hardness materials such as tool steels, wear-resistant alloy steels, etc. These end mills have better wear resistance and cutting performance, allowing for higher machining precision and efficiency on high-hardness materials.

Product Features:

1. High-quality material: The 2-blade ball end mill series uses carbide as the main material, which has high hardness and wear resistance. It can maintain the stability and durability of the tool during high-speed cutting.

2. Multiple specifications available: The series includes three specifications - HRC45, HRC55, and HRC65, which are suitable for processing materials with hardness within 45 degrees, 55 degrees, and 65 degrees respectively, meeting the needs of different customers.

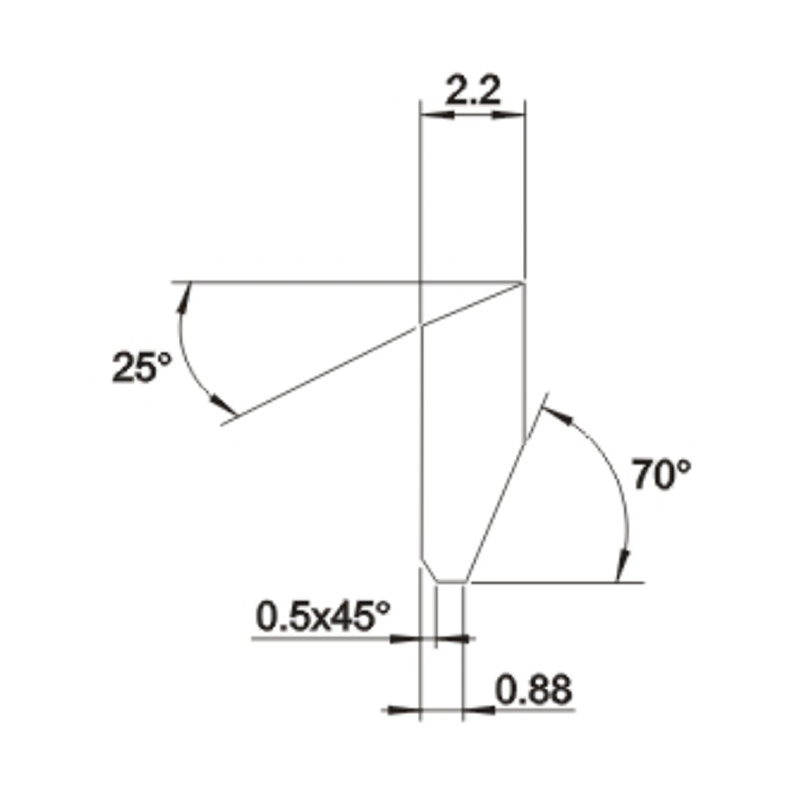

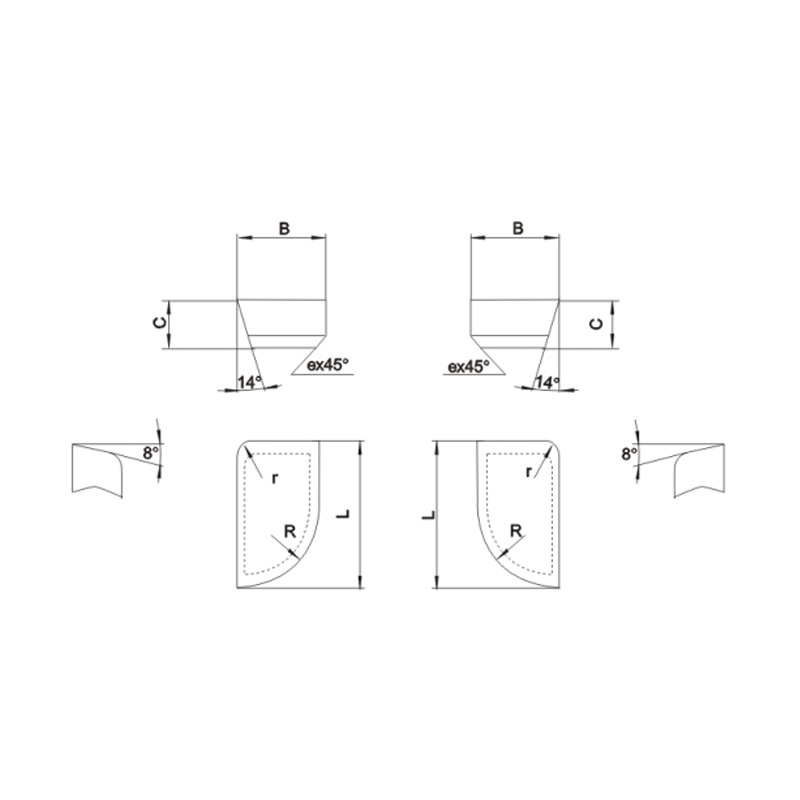

3. High precision machining: The blade design of the 2-blade ball end mill series is precise, enabling high-precision cutting and ensuring the quality and accuracy of the product.

4. High cutting efficiency: Due to the use of carbide material, the 2-blade ball end mill series has high cutting efficiency, allowing for the completion of a large amount of cutting work in a short time, improving production efficiency.

5. Long service life: The carbide material tools have high wear resistance, making the service life of the 2-blade ball end mill series far exceed that of traditional tools, saving customers a lot of replacement costs.

Product Advantages:

1. Strong adaptability: The 2-blade ball end mill series provides three specifications of tools - HRC45, HRC55, and HRC65, which can meet the processing needs of materials with different hardness levels, showing strong adaptability.

2. High cutting precision: The blade design of the 2-blade ball end mill series is precise, enabling high-precision cutting and ensuring the quality and accuracy of the product, meeting customers' high requirements for product quality.

3. High cutting efficiency: The carbide material tools have high cutting efficiency, and the 2-blade ball end mill series can complete a large amount of cutting work in a short time, greatly improving production efficiency.

4. Long service life: The carbide material tools have high wear resistance, making the service life of the 2-blade ball end mill series far exceed that of traditional tools, saving customers a lot of replacement costs.

5. Easy maintenance: The tool structure of the 2-blade ball end mill series is simple, making maintenance convenient, greatly reducing the customer's usage cost.

Product Applications:

The 2-blade ball end mill series is widely used in cutting processing of various hardness materials, such as mold manufacturing, automotive parts manufacturing, etc. Whether it is HRC45, HRC55 or HRC65, it can provide customers with efficient and accurate cutting processing solutions.

Product Packaging:

We use professional packaging methods to ensure the safety of the 2-blade ball end mill series during transportation and prevent damage caused by improper packaging.

In summary, the 2-blade ball end mill series provides customers with efficient and accurate cutting processing solutions with its good material quality, high precision machining, high cutting efficiency, and long service life. Whether it is HRC45, HRC55 or HRC65, it can meet various customer needs. We provide comprehensive product services and professional technical support to ensure that customers can smoothly and efficiently use the 2-blade ball end mill series.

English

English 中文简体

中文简体 русский

русский