Welcome to our grinding tool supply company's website, where we introduce you to our premier product: Carbide Burrs Taper. Crafted with precision and expertise, this tool stands as a testament to the exceptional quality and performance that our products offer. Let's delve into its standout features, applications, and benefits:

Product Overview:

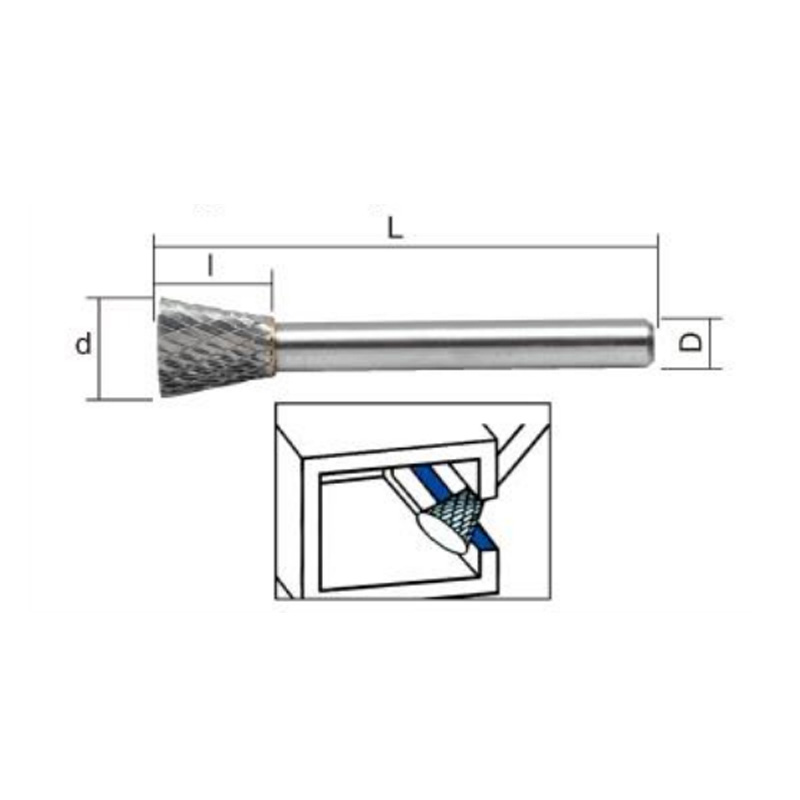

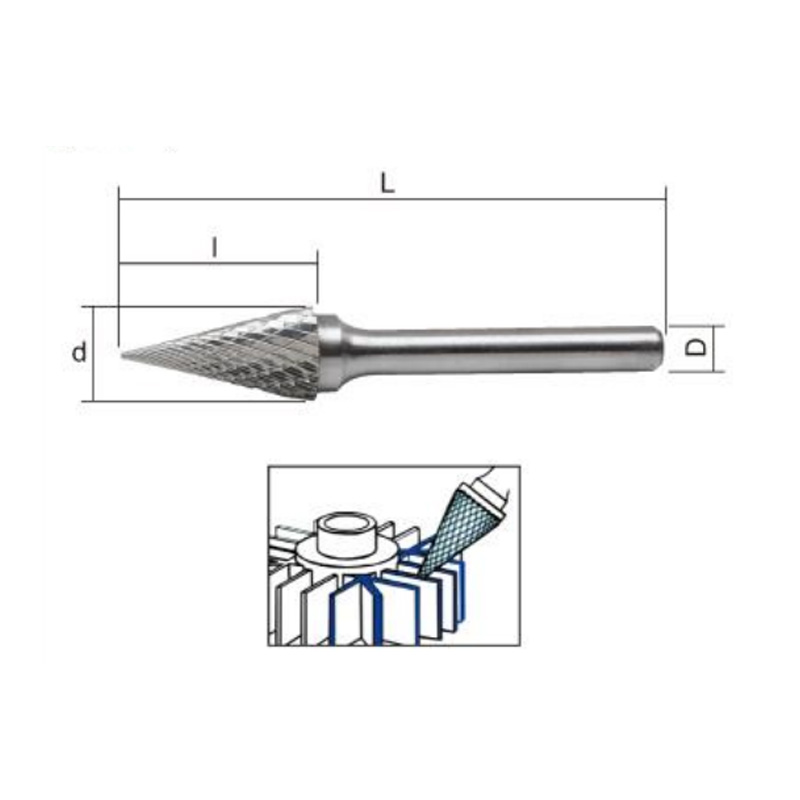

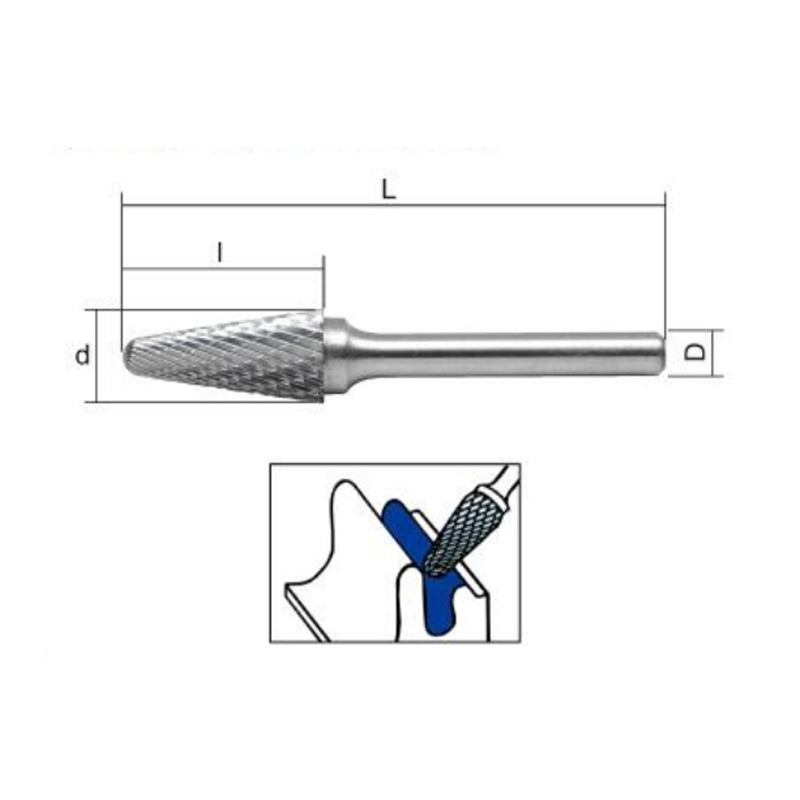

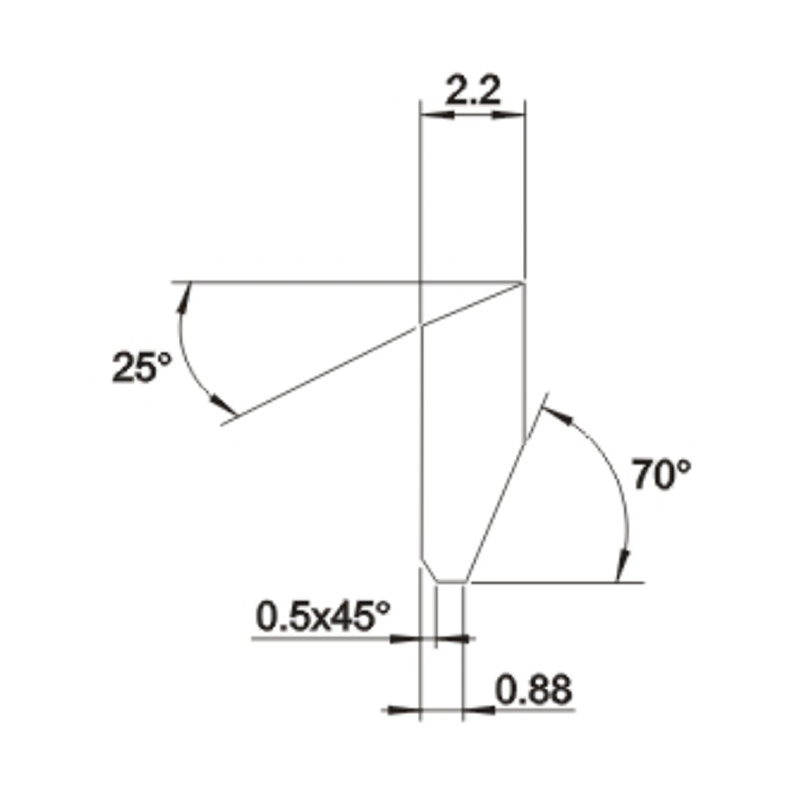

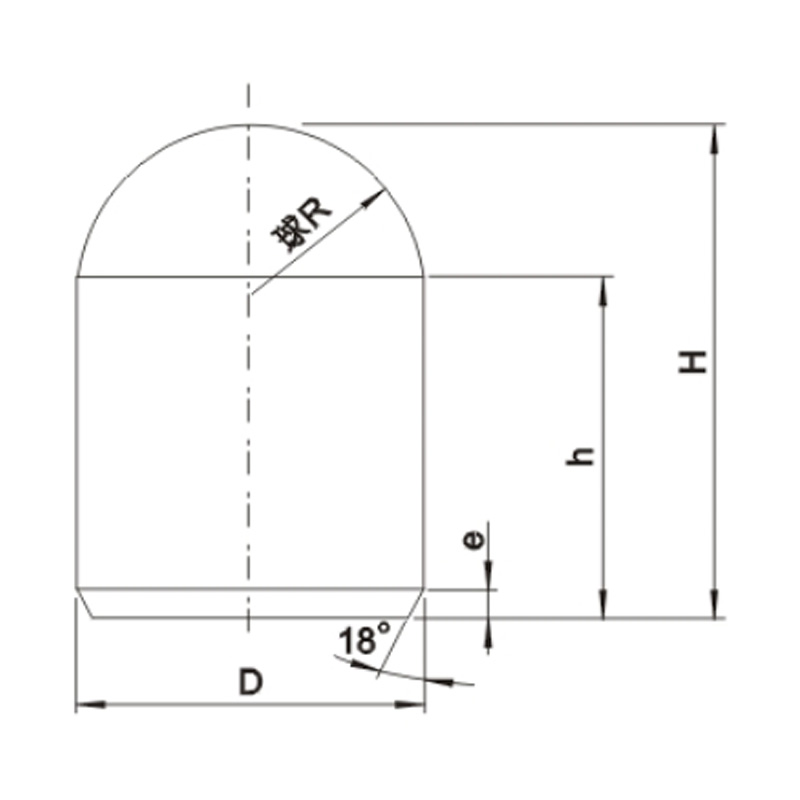

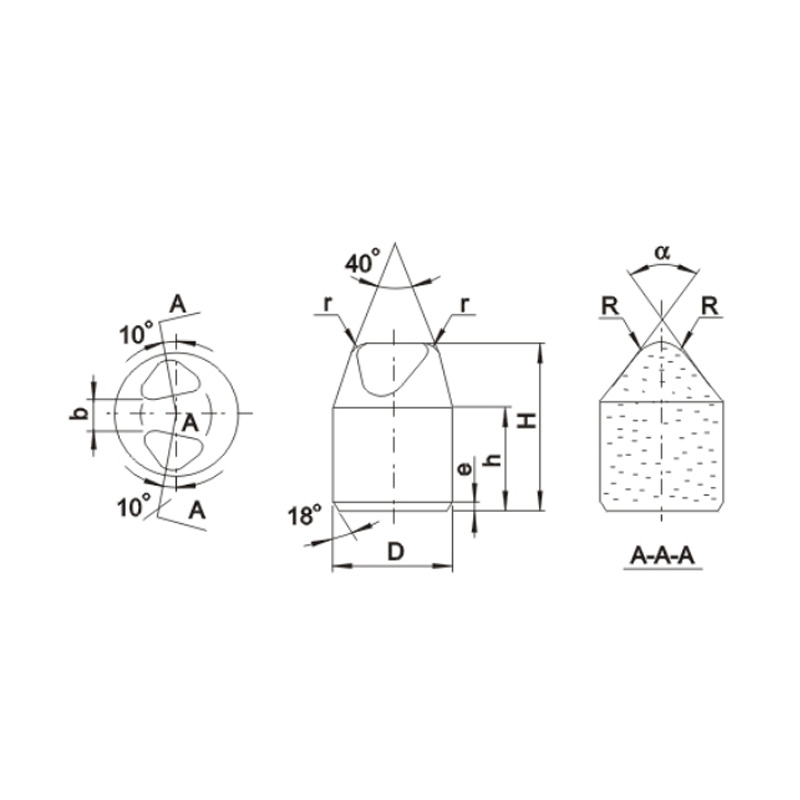

Carbide Burrs Taper is a versatile cutting tool designed for precision machining on both flat and contoured surfaces. Its tapered head shape allows for efficient material removal and precise shaping, making it an indispensable tool in various machining applications. Let's explore some of its key advantages:

Product Advantages:

1.Uniform Cutting Force Distribution:

The tapered design of Carbide Burrs Taper ensures that cutting forces are evenly distributed, resulting in consistent and efficient material removal. This uniform cutting force distribution pilots to improved cutting performance and extended tool life, saving time and resources in the long run.

Additionally, the uniform cutting force distribution minimizes vibration and heat buildup during machining, contributing to smoother surface finishes and reducing the risk of tool wear and damage, enhancing overall machining efficiency and productivity.

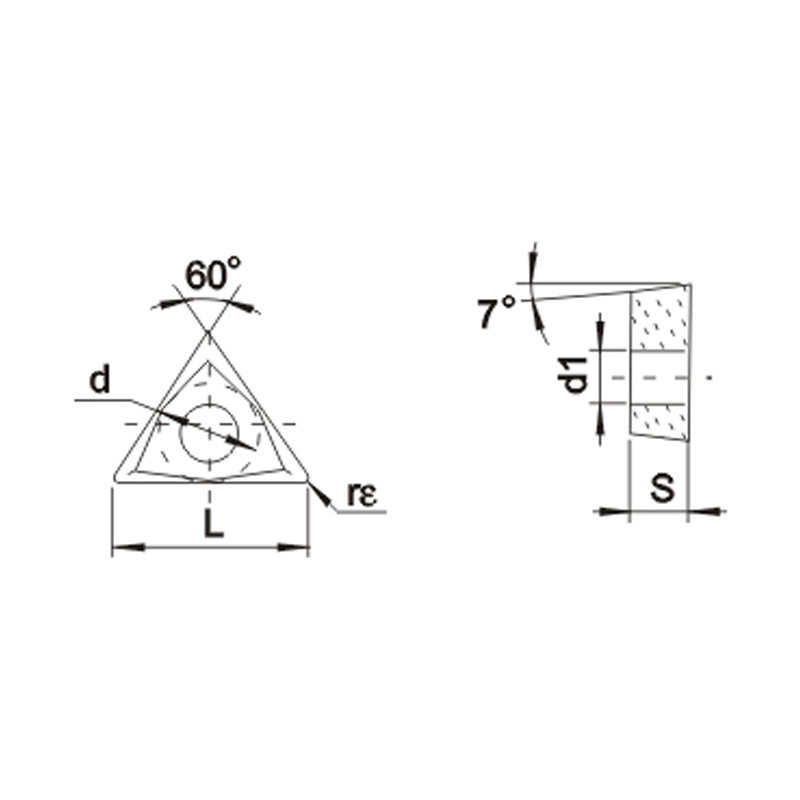

2.Superior Cutting Performance:

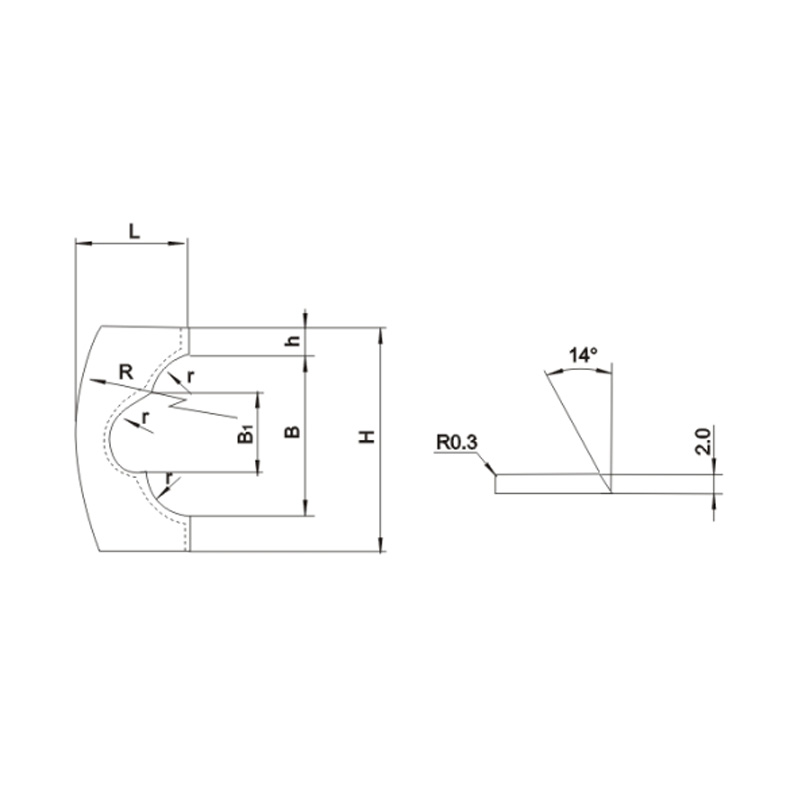

With its precision-engineered carbide construction, Carbide Burrs Taper delivers exceptional cutting performance on both flat and contoured surfaces. Whether you're deburring, shaping, or finishing, this tool provides clean and precise cuts, enhancing the quality and accuracy of your machining operations.

Its advanced carbide construction ensures ideal hardness and wear resistance, allowing for consistent cutting performance even in demanding machining conditions. From deburring to intricate shaping, Carbide Burrs Taper delivers precise results, elevating machining quality and efficiency.

3.Long Service Life:

Thanks to its high-quality carbide material and optimized cutting geometry, Carbide Burrs Taper offers a long service life, reducing the need for frequent tool replacements. This durability translates to cost savings and improved productivity for your machining processes.

Moreover, the combination of high-quality carbide and optimized cutting geometry enhances the tool's resistance to wear and prolongs its lifespan, resulting in fewer interruptions and increased productivity, ultimately pilot to greater cost-effectiveness in machining operations.

Product Applications:

1.Angle and Shape Adjustment:

Carbide Burrs Taper is ideal for trimming and adjusting the angles and shapes of workpieces in various industries, including automotive, aerospace, and manufacturing. Its tapered design allows for precise material removal, enabling you to achieve the desired angles and contours with ease.

2.Deburring and Edge Smoothing:

Whether you're working with metal, wood, or composite materials, Carbide Burrs Taper excels in deburring and smoothing rough edges. Its efficient cutting action removes burrs and sharp edges, resulting in smooth and polished surfaces that meet high-quality standards.

3.Surface Finishing and Detailing:

Carbide Burrs Taper is also widely used for surface finishing and detailing tasks, such as engraving, grooving, and texturing. Its versatile design and ideal cutting performance make it suitable for creating intricate patterns and designs on a variety of materials.

In conclusion, Carbide Burrs Taper is a versatile and reliable cutting tool that offers exceptional performance and durability in a wide range of machining applications. Its tapered design, uniform cutting force distribution, and long service life make it an indispensable tool for precision machining operations. Invest in Carbide Burrs Taper and elevate the quality and efficiency of your machining processes today.

English

English 中文简体

中文简体 русский

русский