Product Parameters:

1. HRC45 Series: This series typically represents end mills with lower hardness, suitable for machining general materials such as softer metals and plastics. These tools offer reasonable cutting performance and wear resistance.

2. HRC55 Series: This level indicates end mills with medium hardness, typically used for machining materials of moderate hardness such as common steels, cast iron, etc. End mills with HRC55 hardness offer better wear resistance and longer service life compared to HRC45 series.

3.HRC65 Series: This is a very high hardness level suitable for machining high-hardness materials such as stainless steel, alloy steels, etc. End mills with HRC65 hardness typically exhibit wear resistance and cutting performance, suitable for high-precision machining and prolonged usage.

Product Features:

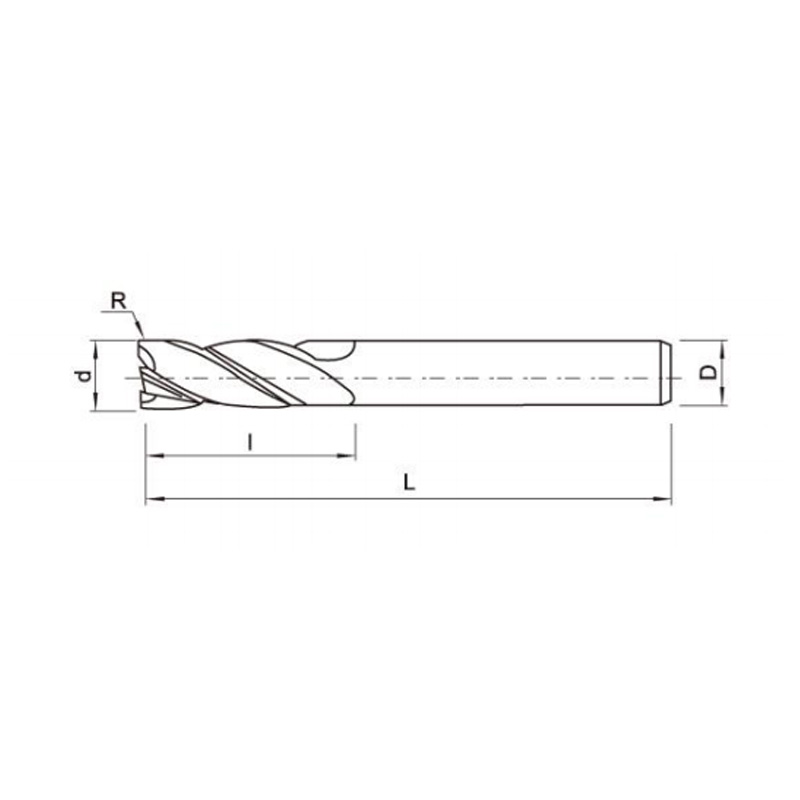

1. High-quality Material: The 4-edge round nose end mill series uses hard alloy as the main material, which has high hardness and wear resistance. It can maintain the stability and durability of the tool during high-speed cutting.

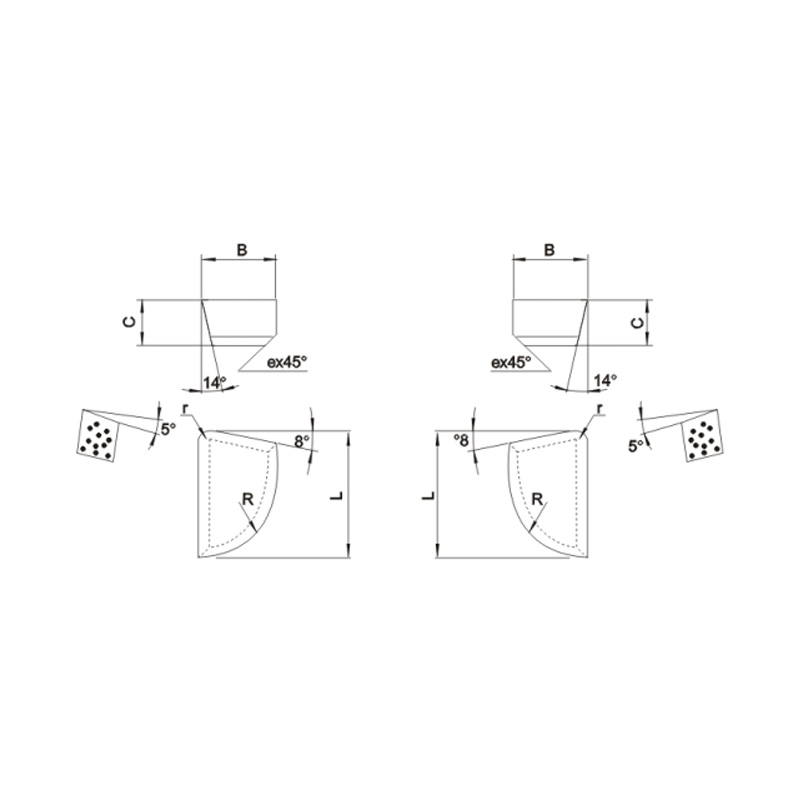

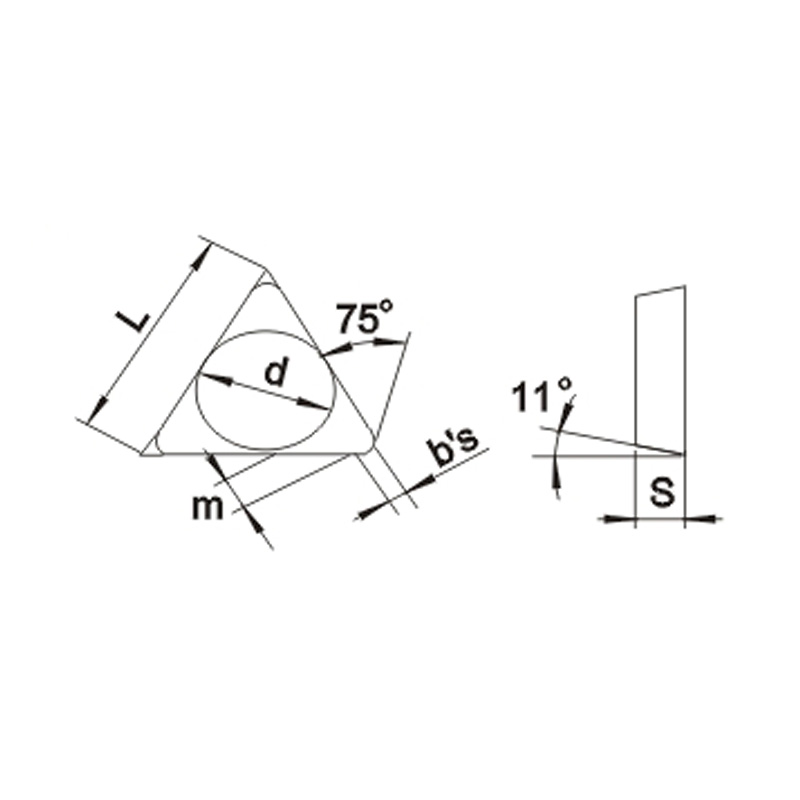

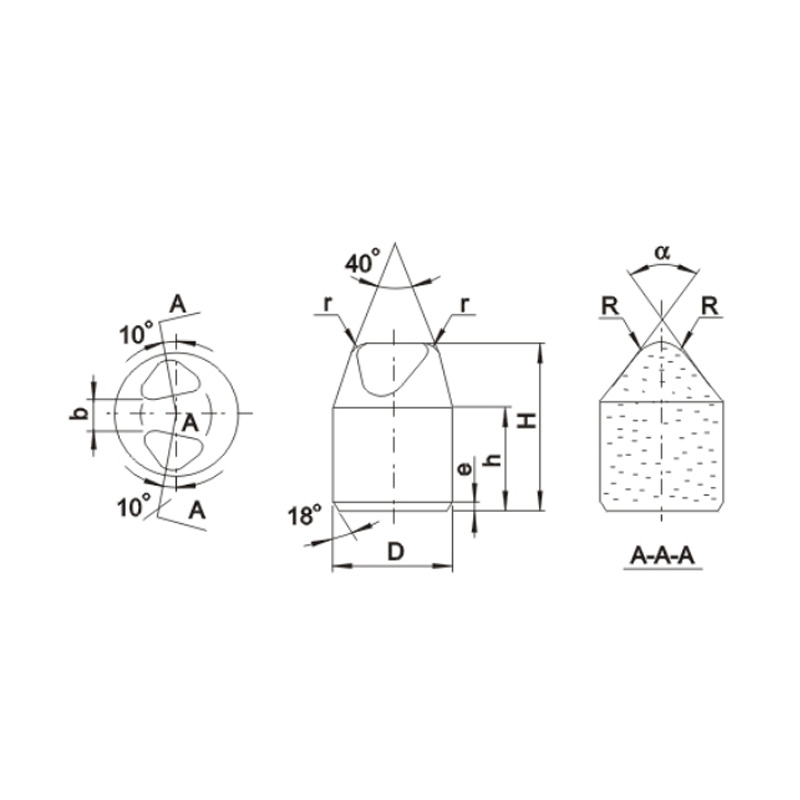

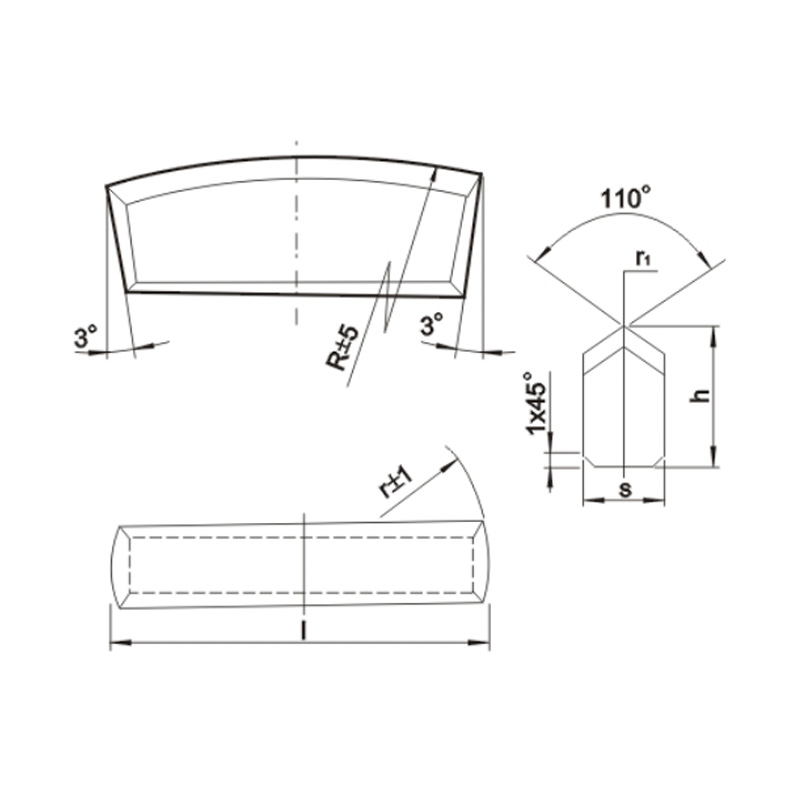

2. Four-edge Design: This series of end mills adopts a four-edge design, providing a larger cutting area, improving cutting efficiency, and reducing cutting force to reduce tool wear.

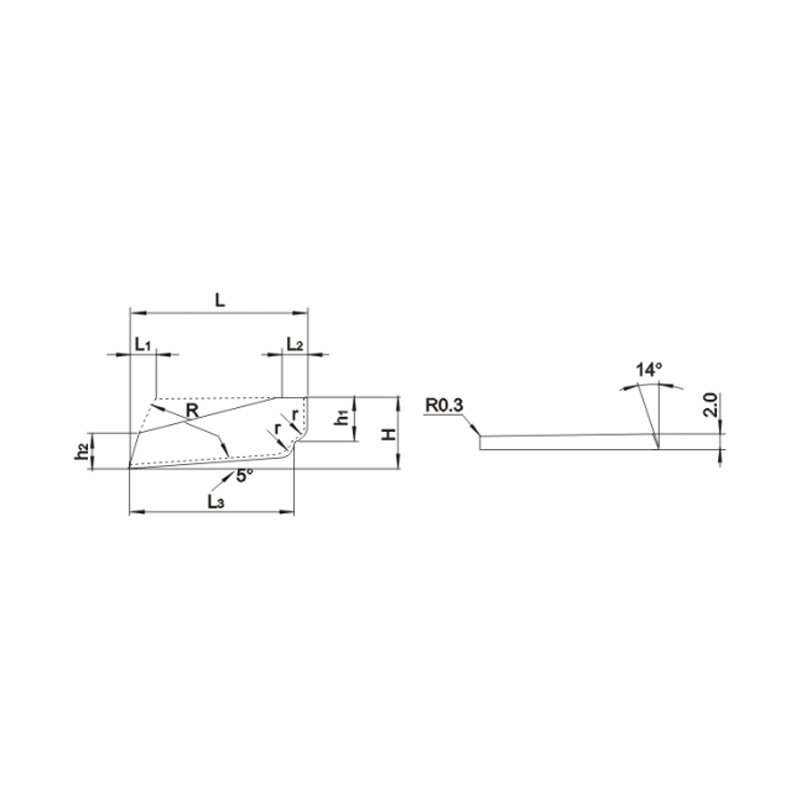

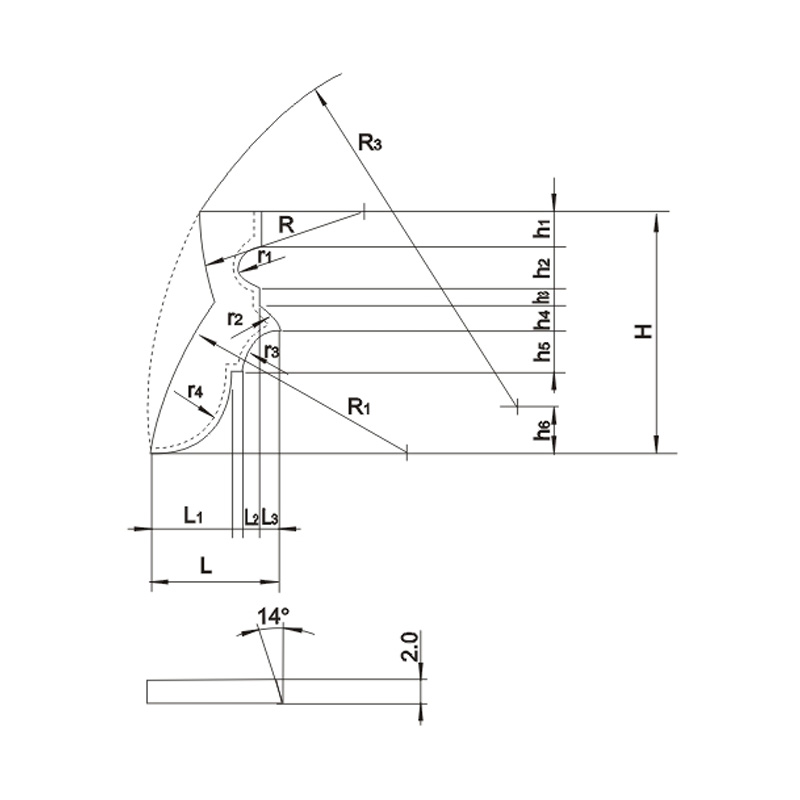

3. Round Nose Design: The round nose design provides better cutting stability, reduces vibration during cutting, and improves processing accuracy.

4. Multiple Hardness Options: This series of end mills offers three hardness options: HRC45, HRC55, and HRC65, to meet the processing needs of different materials. HRC45 is suitable for materials with a hardness of up to 45 degrees, HRC55 is suitable for materials with a hardness of up to 55 degrees, and HRC65 is suitable for materials with a hardness of up to 65 degrees.

Product Advantages:

1. Efficient Cutting: Hard alloy end mills have high hardness and wear resistance, maintaining the stability and durability of the tool during high-speed cutting, improving cutting efficiency.

2. High Precision Processing: The four-edge design and round nose design provide better cutting stability, reduce vibration during cutting, and improve processing accuracy.

3. Long Lifespan: Hard alloy end mills have high wear resistance, maintaining good cutting performance after long-term use, extending the service life of the tool.

4. Multiple Hardness Options: This series of end mills offers three hardness options to meet the processing needs of different materials, improving product versatility.

Product Applications:

1. Metal Processing: The 4-edge round nose end mill series is suitable for processing various metal materials, including aluminum, copper, steel, etc.

2. Mold Manufacturing: This series of end mills can be used for precision machining of molds, such as cavity and core.

3. Electronic Parts Manufacturing: This series of end mills can be used for precision machining of electronic parts, such as micro motors and micro gears.

In summary, the 4-edge round nose end mill series is widely used in metal processing, mold manufacturing, electronic parts manufacturing, etc. due to its material quality, efficient cutting performance, high precision processing effect, long lifespan characteristics, and multiple hardness options advantages. We provide professional technical support, customized services, and after-sales guarantees to provide customers with products and services.

English

English 中文简体

中文简体 русский

русский