Welcome to our product page featuring the 95 Degree External Turning, Facing, and Boring Tools! Designed to meet the diverse needs of machining operations, these tools offer versatility, precision, and efficiency for a wide range of applications. Let's delve into the unique advantages, features, and applications of these cutting-edge tools.

Product Advantages:

Expanded Angle Range:

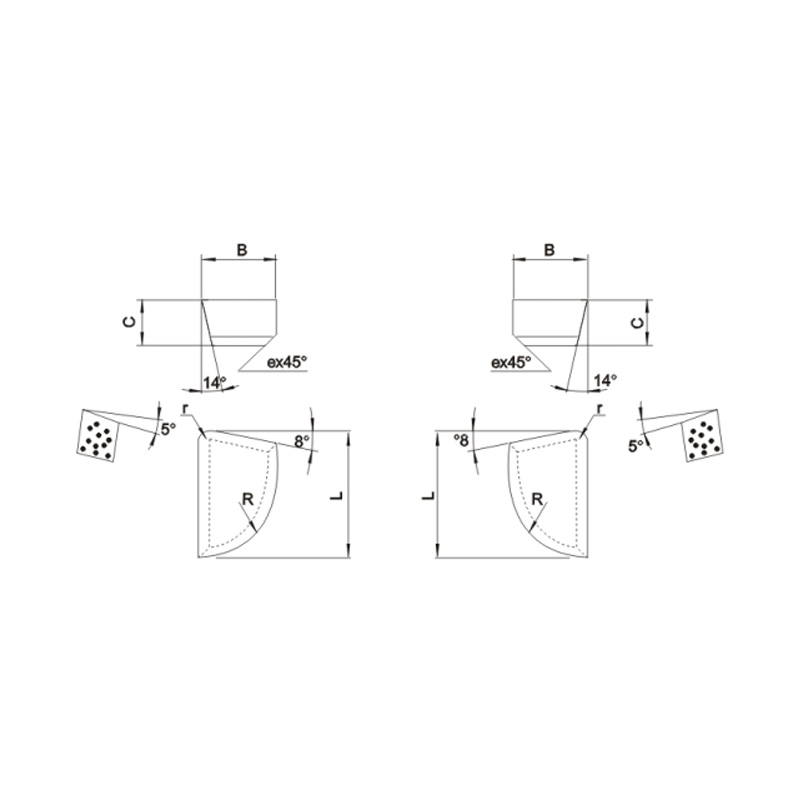

- Versatility: The larger angle range of the 95 Degree External Turning, Facing, and Boring Tools allows for a wider range of machining operations on diverse workpieces. This versatility enables machinists to tackle complex geometries and unique profiles with ease.

- Flexibility: With a broader angle range, these tools offer increased flexibility in adjusting cutting paths and approaches, accommodating various machining requirements without the need for additional tooling setups.

- Adaptability: The expanded angle range makes these tools adaptable to different materials, workpiece sizes, and machining conditions, enhancing their utility across a spectrum of machining applications.

Multi-Functionality:

- Comprehensive Machining Solution: The ability to perform external turning, facing, and boring operations within a single tool offers a comprehensive solution for machining complex workpieces. Machinists can complete multiple machining tasks with a single setup, reducing downtime and increasing efficiency.

- Streamlined Operations: With multi-functionality built into one tool, machining operations become streamlined, eliminating the need for frequent tool changes and setup adjustments. This simplifies the machining process, saving time and resources.

Improved Efficiency:

- Increased Productivity: The wider angle range of the 95 Degree Tools enables machinists to perform a variety of machining tasks without interrupting the workflow for tool changes or setup adjustments. This pilots to enhanced productivity as machining processes can proceed seamlessly.

- Reduced Downtime: Minimizing tool changes and setup adjustments reduces downtime associated with machining operations. Machinists can focus on machining tasks without interruptions, optimizing machine utilization and overall efficiency.

Product Features:

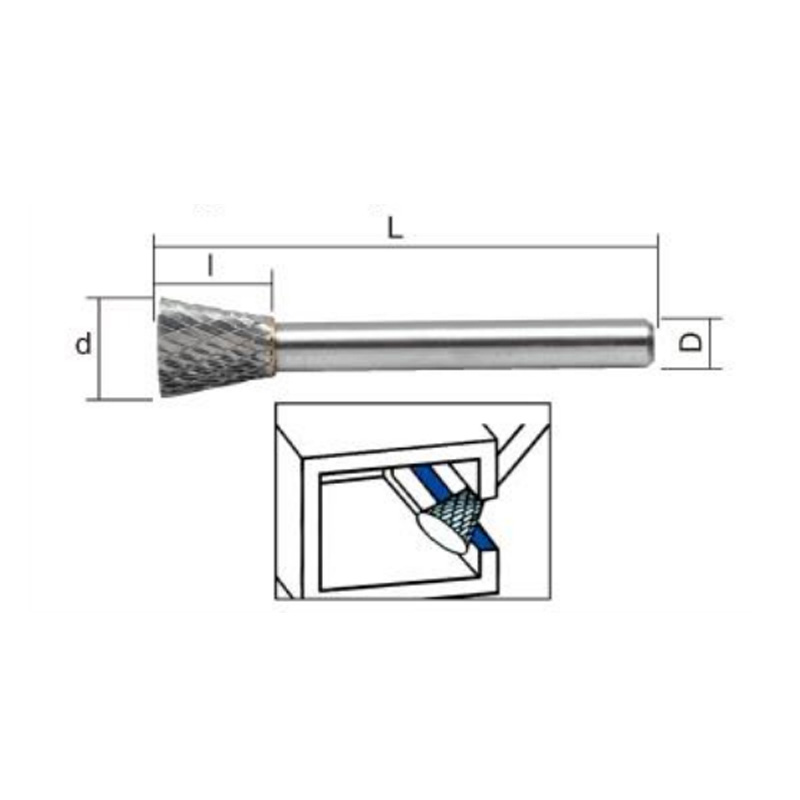

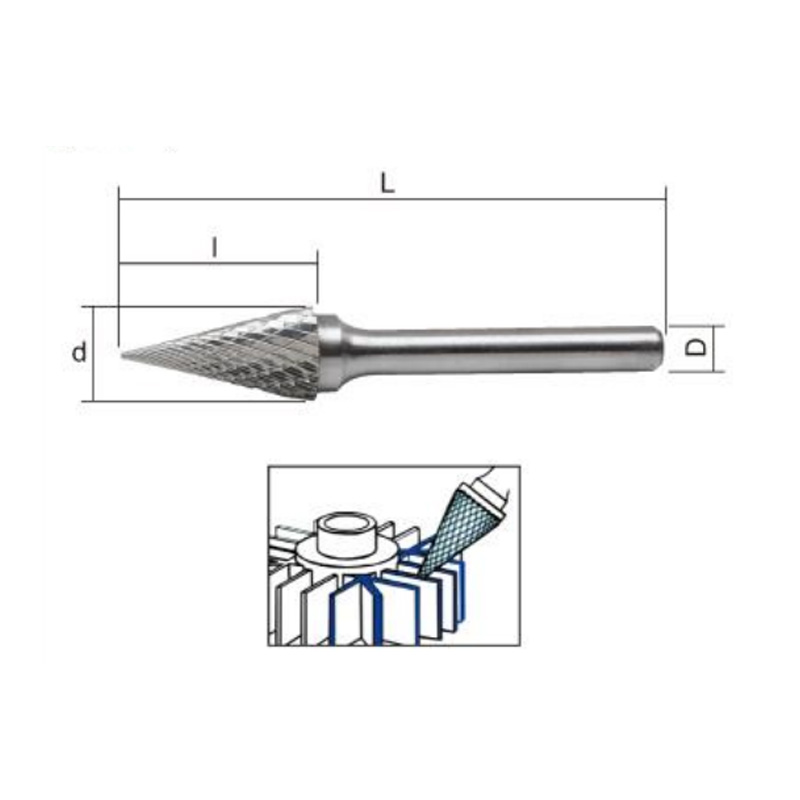

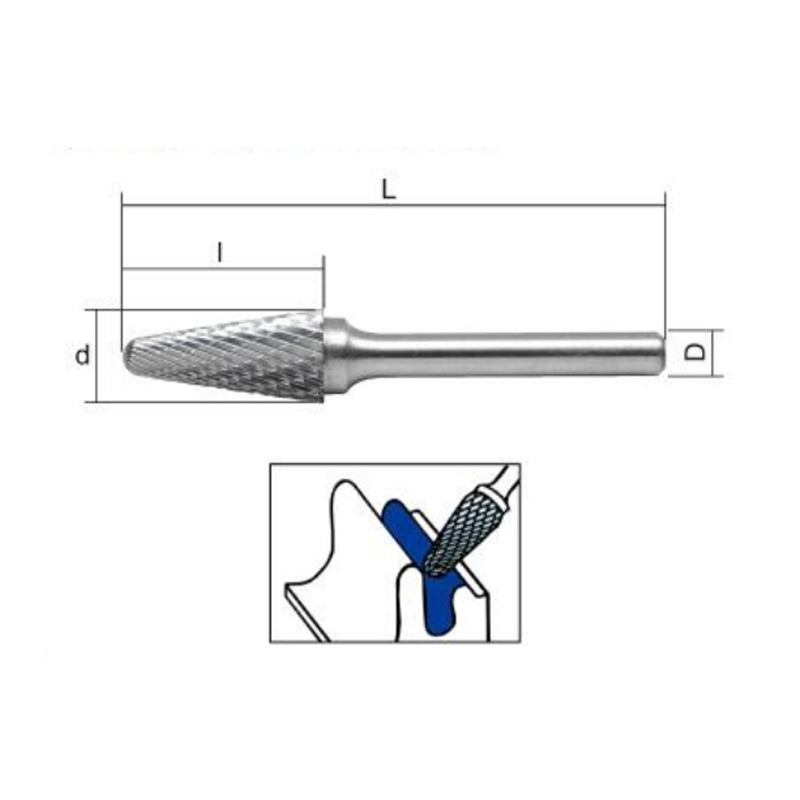

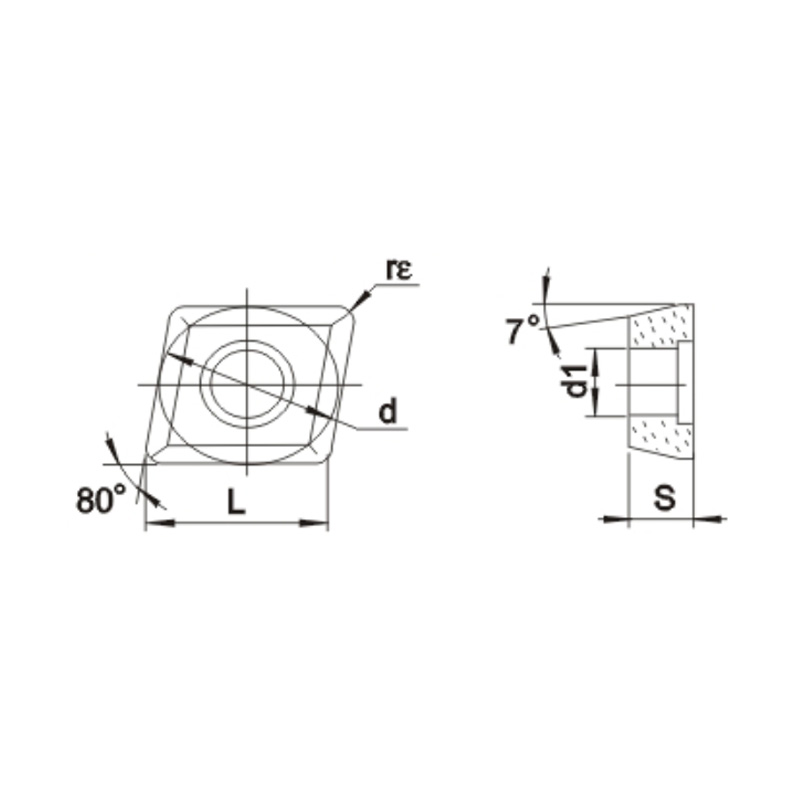

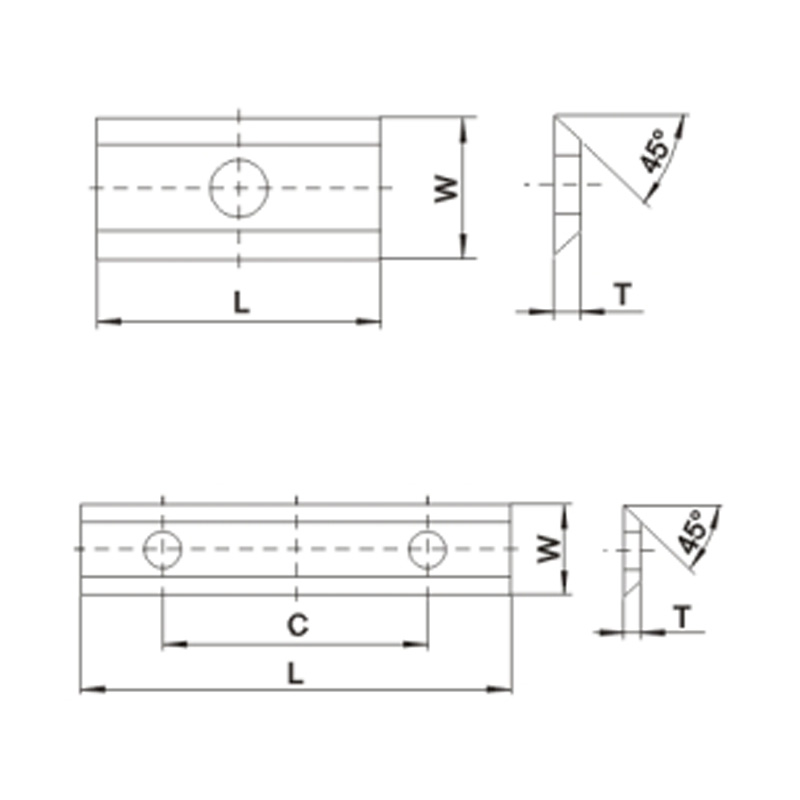

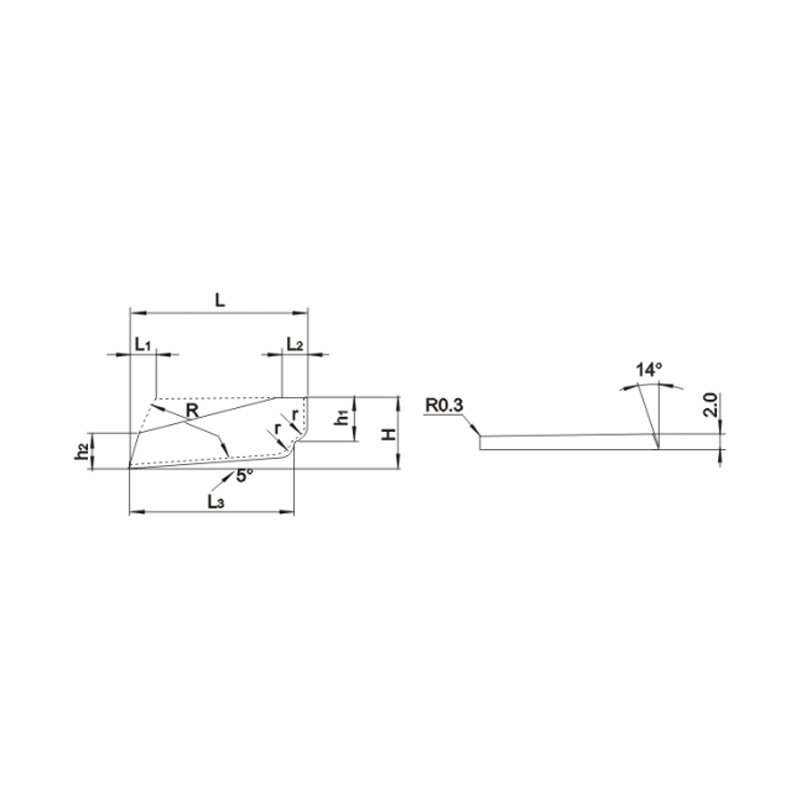

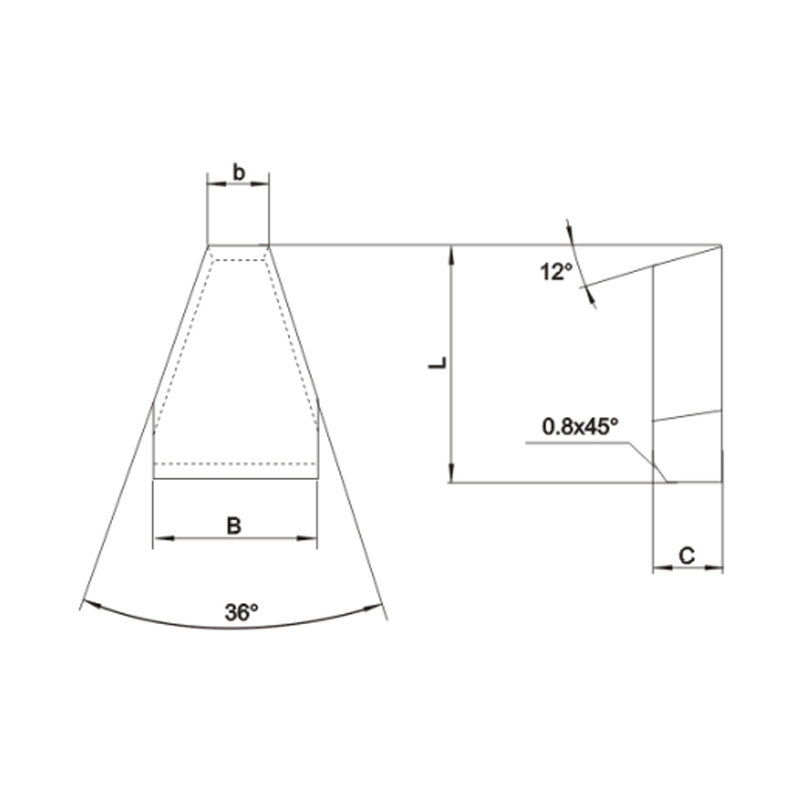

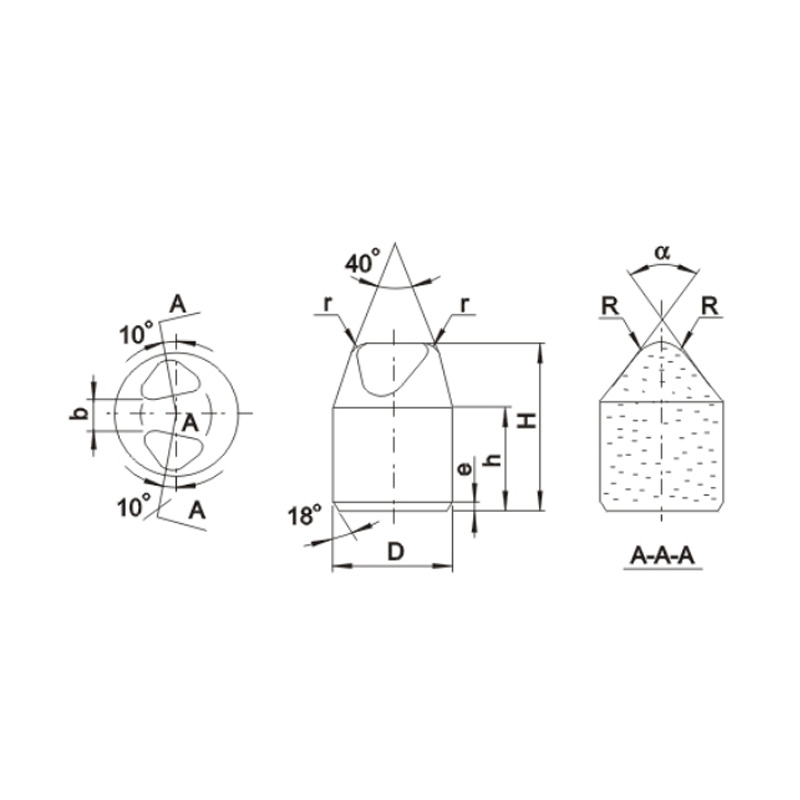

- Versatile Machining: The 95 Degree External Turning, Facing, and Boring Tools are capable of machining external diameters, facing surfaces, and internal bores, making them suitable for a diverse range of workpieces.

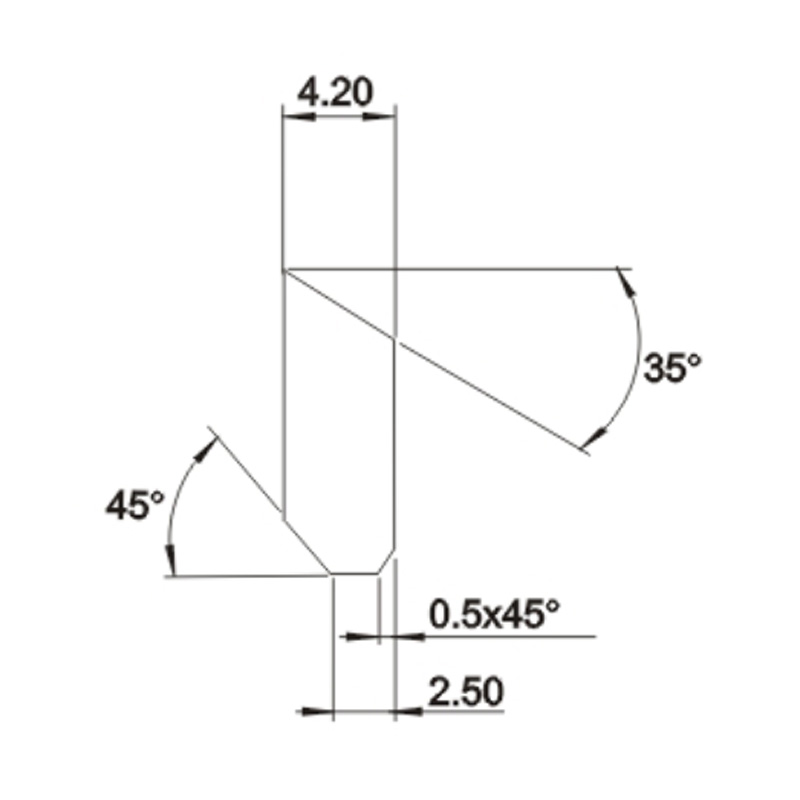

- Precision Engineering: Engineered with precision and attention to detail, these tools ensure accurate and consistent machining results, meeting tight tolerances and quality standards.

- Durable Construction: Crafted from high-quality materials and advanced coatings, these tools are built to withstand the demands of heavy-duty machining operations, ensuring long-lasting performance and reliability.

Product Applications:

- Complex Workpieces: Ideal for machining complex workpieces that require simultaneous external turning, facing, and boring operations. These tools excel in applications where multiple machining operations are needed to complete a single workpiece or a series of parts.

- Automotive Industry: Widely used in the automotive industry for machining engine components, transmission parts, and other critical components that demand precision and versatility.

- Aerospace Sector: Trusted by aerospace manufacturers for machining aerospace components with intricate geometries and tight tolerances. These tools ensure the precise machining of critical aircraft parts, such as engine housings and structural components.

In conclusion, the 95 Degree External Turning, Facing, and Boring Tools offer a comprehensive solution for machining operations, combining versatility, precision, and efficiency. With their expanded angle range, multi-functionality, and durable construction, these tools are the go-to choice for machining complex workpieces across various industries. Invest in our 95 Degree Tools and experience enhanced productivity, quality, and performance in your machining operations.

English

English 中文简体

中文简体 русский

русский