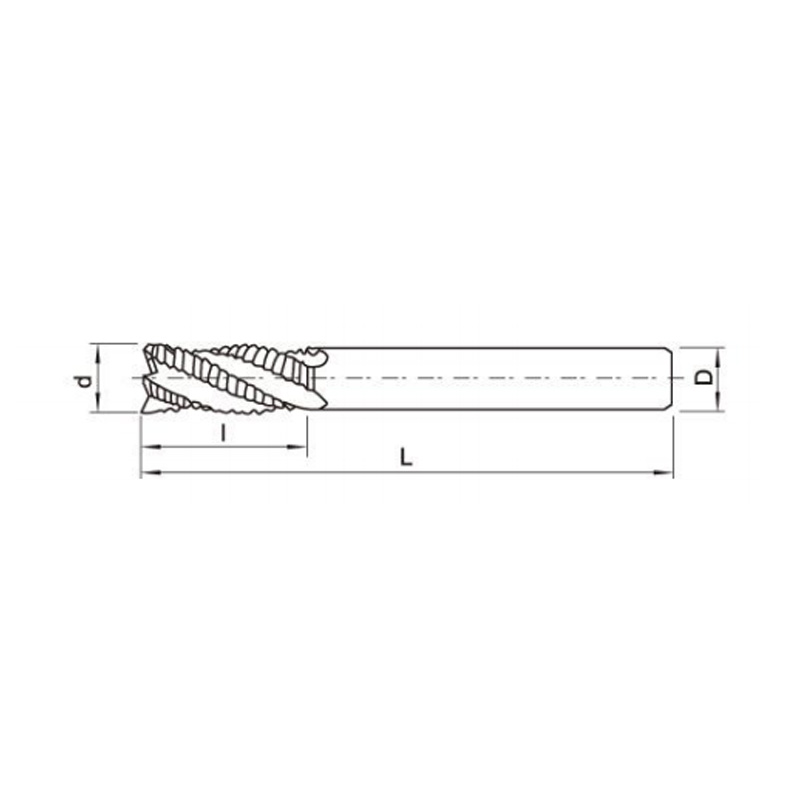

Product Specifications:

1. HRC45: This indicates a hardness of 45 HRC (Rockwell hardness C scale), which is relatively low. Generally, HRC45 milling cutters are suitable for machining softer materials such as aluminum. The edges of these cutters may be relatively sharp, suitable for finer machining of materials, but may not be ideal for machining harder materials such as steel.

2. HRC55: This is a medium hardness level, slightly harder than HRC45. HRC55 milling cutters are suitable for some higher hardness materials, such as certain types of steel. Compared to HRC45 milling cutters, they may be more wear-resistant and suitable for more challenging machining tasks.

3. HRC65: This is a relatively high hardness level. HRC65 milling cutters are suitable for machining badly hard materials, such as tool steel or special alloy steels. These high hardness cutters may be more wear-resistant, but may not be as suitable for machining softer materials, as they could be prone to tool wear or damage.

Product Features:

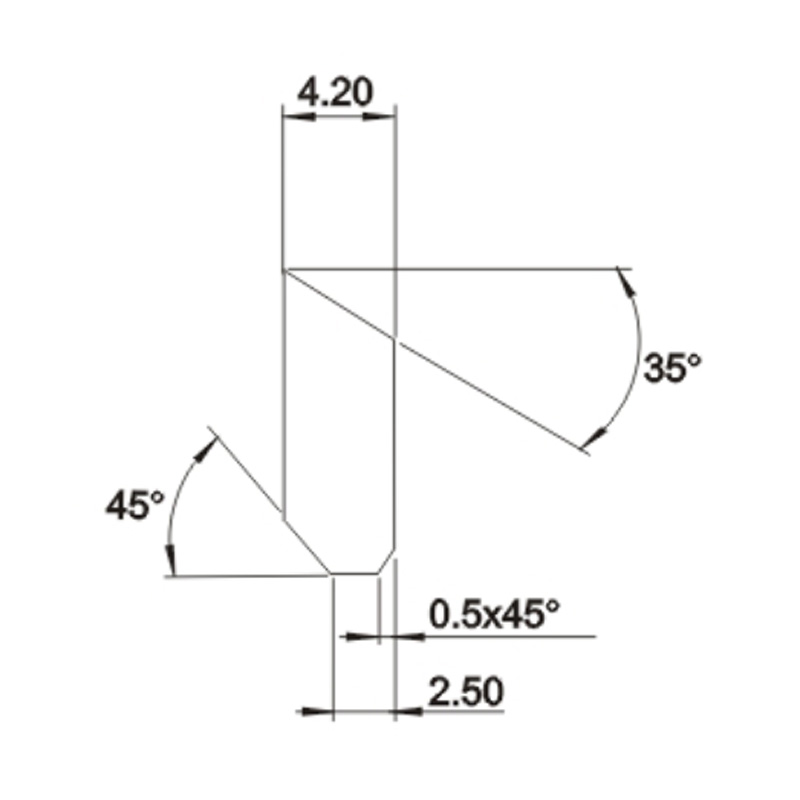

1. High-quality Material: This series of aluminum and steel rough skin end mills uses carbide as the main material, which has high hardness, high strength, and wear resistance. It can effectively resist wear and thermal deformation during high-speed cutting.

2. Multiple Specification Options: This series of end mills provides three specifications (HRC45, HRC55, and HRC65) based on different processing hardness to meet the processing needs of different materials.

3. High Precision Processing: These end mills have undergone precision machining and grinding, ensuring good geometric accuracy and surface quality for achieving high-precision processing results.

4. Long Lifespan: Due to the use of carbide material, this series of end mills has high durability and a long lifespan, reducing the frequency of tool replacement and improving production efficiency.

Product Advantages:

1. Efficient Processing: These end mills have high cutting speeds and feed rates, enabling quick completion of processing tasks and improving production efficiency.

2. High-Quality Processing: Thanks to the use of carbide material and precision machining technology, these end mills can achieve high-quality processing results, ensuring product dimensional accuracy and surface quality.

3. Strong Adaptability: This series of end mills is suitable for processing materials such as aluminum and steel, meeting the needs of different industries and processes and demonstrating strong adaptability.

Product Applications:

1. The aluminum and steel rough skin end mill series is suitable for rough and semi-finish machining of materials such as aluminum and steel, meeting the needs of different industries and processes.

2. These end mills are widely used in the processing of automotive, electronic, household appliance, and other industries' components, such as engine parts, chassis parts, electronic device shells, etc.

3. These end mills are also suitable for mold manufacturing, mechanical processing, and other processing requirements.

The aluminum and steel rough skin end mill series uses carbide material with high hardness, high strength, and wear resistance, enabling high-precision and efficient processing results. This series offers three specifications (HRC45, HRC55, and HRC65) to meet the processing needs of materials with different hardness levels. With advantages such as efficient processing, high-quality processing, strong adaptability, cost savings, and easy operation, these end mills are widely used in the processing of automotive, electronic, household appliance, and other industries' components. Proper maintenance and care should be taken during use to extend the tool's service life.

English

English 中文简体

中文简体 русский

русский