Product Specifications

These descriptions refer to different hardness levels of the tools, as well as their suitability for machining materials. Here, "HRC" stands for "Rockwell hardness scale," and the numbers represent different hardness levels. Typically, HRC45 indicates a hardness of 45, HRC55 indicates a hardness of 55, and so on.

For aluminum alloy machining, it's generally recommended to use tools with different hardness levels to achieve ideal machining results:

1. HRC45: Suitable for general aluminum alloy machining, with lower hardness but able to provide good cutting performance and tool life.

2. HRC55: Higher in hardness compared to HRC45, making it more suitable for processing harder aluminum alloys, offering higher cutting efficiency and longer tool life.

3. HRC65: In hardness, suitable for processing even harder aluminum alloy materials, providing higher cutting speeds and longer tool life, though it may sacrifice some surface finish quality.

Product Features:

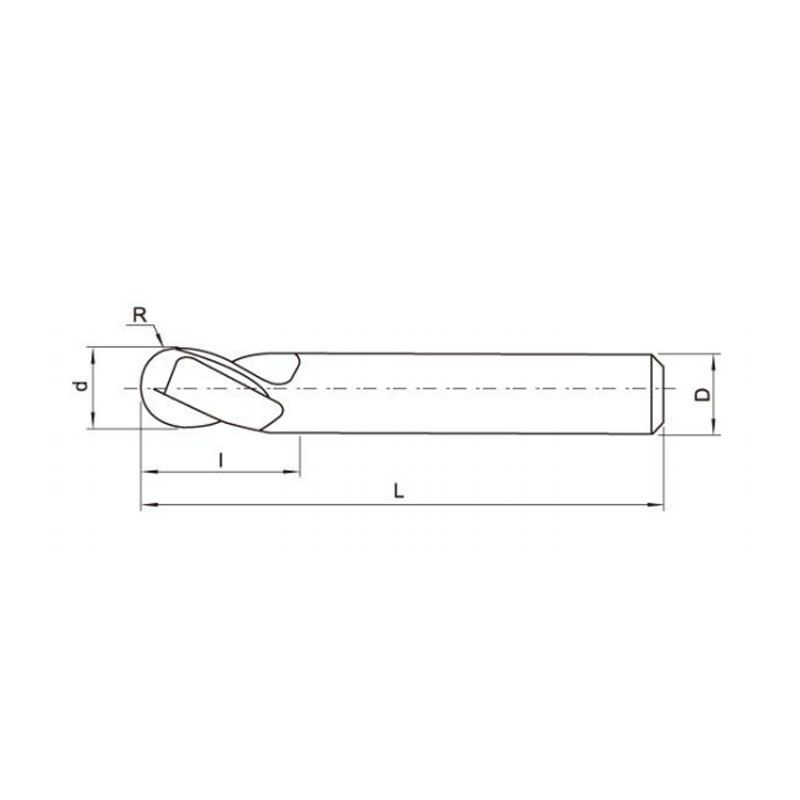

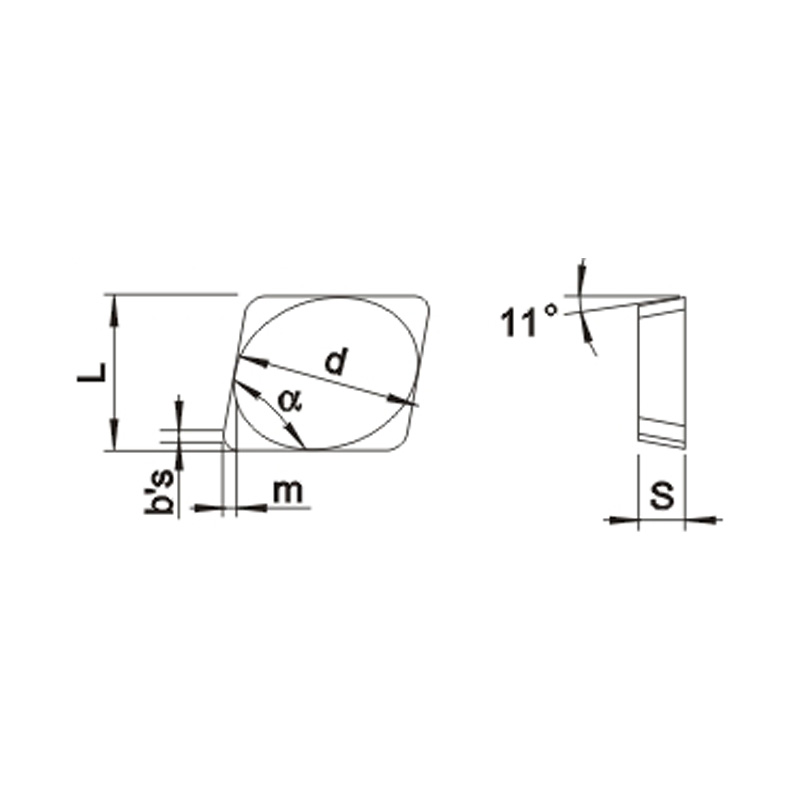

1. High-quality Material: The 2-blade ball head aluminum alloy series uses hard alloy as the main material, which has high hardness and wear resistance. It can maintain stable performance in various harsh working environments.

2. High Hardness: The hardness of this series of products is divided into three types: HRC45, HRC55, and HRC65, which correspond to materials with a processing hardness of 45 degrees, 55 degrees, and 65 degrees respectively. This high hardness feature allows the series of products to maintain cutting performance during processing, improving processing efficiency.

3. Strong Wear Resistance: The wear resistance of hard alloy is very , which makes the 2-blade ball head aluminum alloy series have very small surface wear after long-term use, ensuring product durability.

Product Advantages:

1. High Efficiency: Due to the high hardness and wear resistance of this series of products, they can maintain cutting performance during processing, greatly improving processing efficiency. At the same time, the high precision feature also greatly reduces the waste rate during processing, further improving production efficiency.

2. High Durability: The good wear resistance of hard alloy makes the 2-blade ball head aluminum alloy series have very small surface wear after long-term use, ensuring product durability. This means that users do not need to frequently replace tools, thus saving costs.

3. Wide Applicability: The hardness of this series of products is divided into three types: HRC45, HRC55, and HRC65, which can meet the processing needs of materials with different hardnesses. Whether for soft or hard materials, they can be effectively processed.

4. High Precision: The precision of this series of products is very high, meeting the needs of various precision machining. Whether in rough machining or fine machining processes, it can ensure the dimensional accuracy and shape accuracy of the product. This is a huge advantage for users who need high-precision processing.

Product Application Areas:

1. Automobile Manufacturing: In the process of automobile manufacturing, various metal materials need to be precisely processed. The 2-edged ball head aluminum alloy series products can provide high-precision processing and meet the various needs of automobile manufacturing.

2. Mold Manufacturing: Mold is an important tool in the manufacturing industry, and its precision and durability directly affect the quality of products. The 2-edged ball head aluminum alloy series products can provide high-precision processing, and their high hardness and wear resistance can also meet the needs of mold manufacturing.

3. Electronics and Electrical Appliances: In the field of electronics and electrical appliances, the precision and wear resistance requirements for components are also very high. The 2-edged ball head aluminum alloy series products can provide high-precision processing, and their high hardness and wear resistance can also meet the needs of the electronics and electrical appliances field.

English

English 中文简体

中文简体 русский

русский