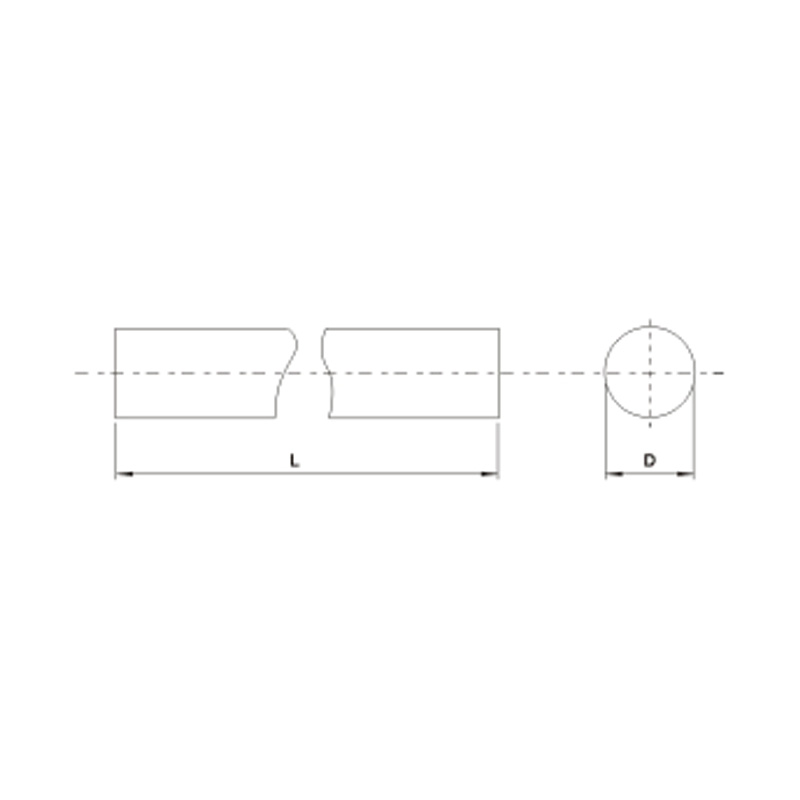

YG6X 10% cobalt, 14.50 density (g/cm³) cemented carbide tungsten rod

Cat:Carbide Rod Series

Welcome to our grinding supplies company's website, where we proudly present our flagship product, the YG6X Carbide Rod....

See DetailsHigh hardness: Cemented carbides have very high hardness, usually between HRA89-93, which makes them very suitable for cutting tools and wear-resistant parts.

High wear resistance: Due to its high hardness, cemented carbides have ear resistance and can maintain performance under harsh working conditions.

Good thermal stability: Cemented carbides can maintain their hardness and strength at high temperatures, which makes them suitable for use in high-temperature environments.

High compressive strength: Cemented carbides have high compressive strength and can withstand large pressures without deformation.

Chemical stability: Cemented carbides resist chemicals and are not easily corroded.

Cemented carbides, known for their exceptional hardness and wear resistance, have become a cornerstone in the manufacturing of cutting tools and wear-resistant components. The unique properties of cemented carbides make them particularly valuable in applications that demand durability and precision. Among these applications, carbide rotary tool bits and carbide burr tools exemplify how these materials enhance performance across various industries.

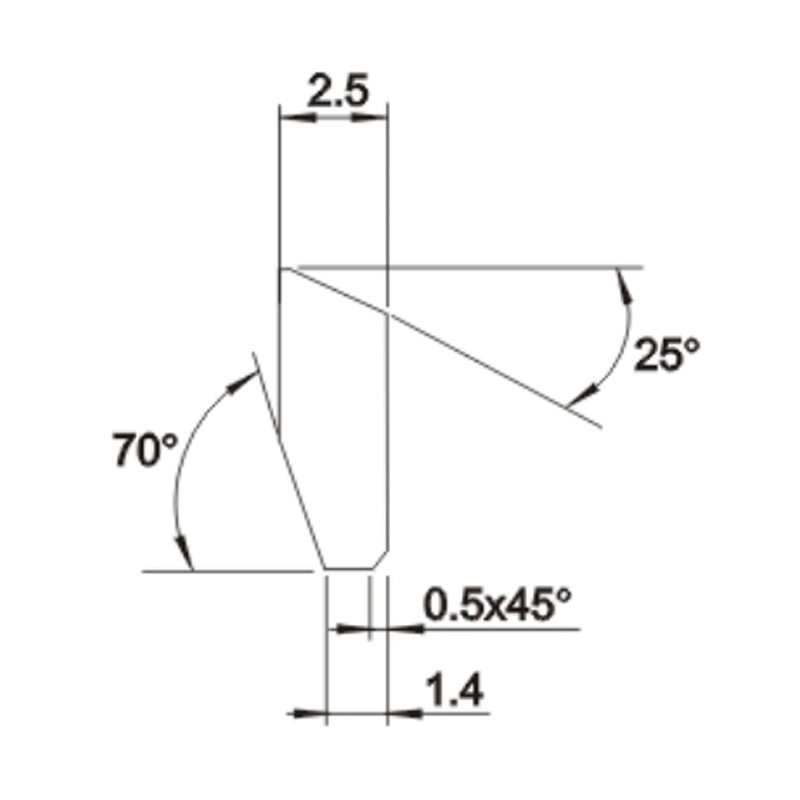

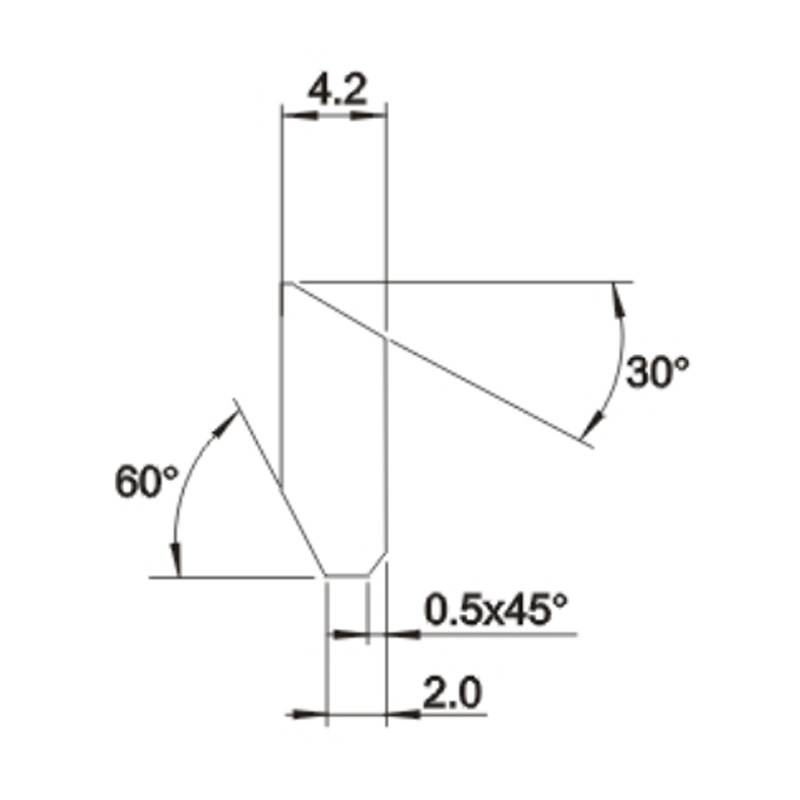

Carbide rotary tool bits are commonly used in machining, drilling, and shaping materials. Their high hardness allows them to cut through metals, plastics, and composites with ease, providing clean and accurate finishes. The sharp edges of carbide rotary tool bits ensure efficient material removal while reducing the risk of tool wear and degradation. As a result, these tools can maintain their cutting capabilities even under demanding conditions, making them essential in manufacturing processes.

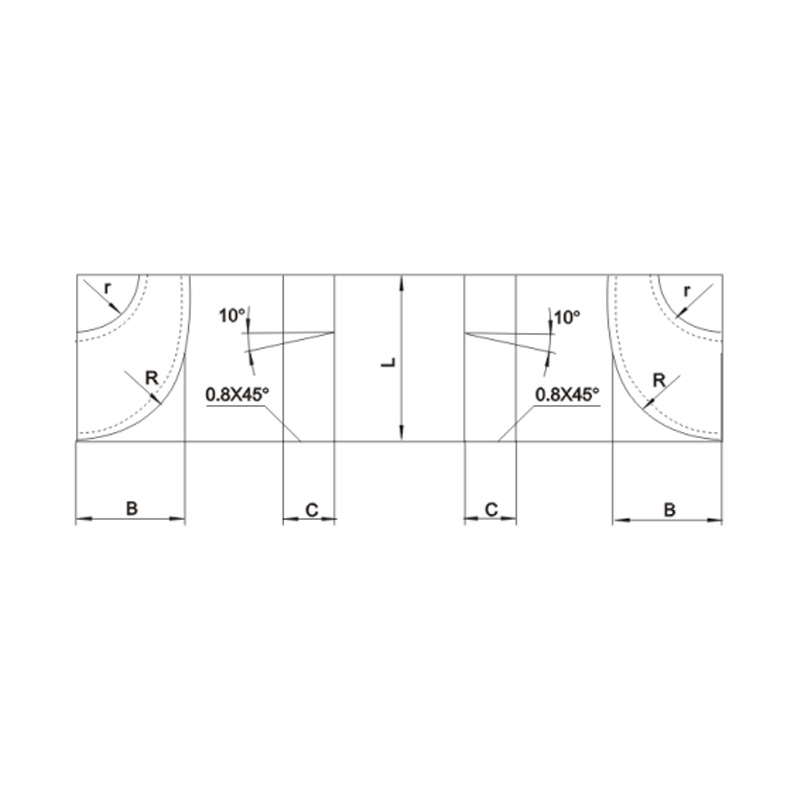

The design of carbide rotary tool bits is engineered to maximize performance. The geometry of the cutting edge plays a crucial role in determining how effectively the tool can perform. Various shapes and sizes are available to cater to specific applications, such as drilling holes or creating intricate patterns. This versatility allows manufacturers to select the appropriate carbide rotary tool bit for their specific needs, enhancing productivity and efficiency in their operations.

In addition to rotary tool bits, carbide burr tools are another vital application of cemented carbides. These tools are typically used for grinding, shaping, and removing material from a workpiece. Carbide burr tools feature a head with multiple cutting edges, allowing for rapid material removal and intricate shaping. The high wear resistance of carbide burr tools enables them to withstand the rigors of heavy use, ensuring they remain effective over time.

One of the key advantages of carbide burr tools is their ability to work on a variety of materials, including metals, wood, and plastics. This versatility makes them a popular choice in industries ranging from automotive to woodworking. For example, in the automotive industry, carbide burr tools are often used for deburring and finishing parts, ensuring a smooth surface that meets stringent quality standards. In woodworking, these tools help artisans create detailed designs and shapes, allowing for creative expression while maintaining the integrity of the material.

The thermal stability of cemented carbides also contributes to the effectiveness of carbide rotary tool bits and carbide burr tools. In high-temperature environments, such as those encountered during machining processes, these tools retain their hardness and strength. This characteristic is particularly beneficial in applications involving high-speed machining, where excessive heat can advance to tool failure. The ability of carbide tools to withstand such conditions ensures consistent performance and reduces the likelihood of downtime due to tool replacement.

Moreover, the chemical stability of cemented carbides enhances their usability in various environments. These tools resist corrosion and degradation from exposure to chemicals, making them suitable for applications in the chemical and pharmaceutical industries. When using carbide rotary tool bits and burr tools in environments with aggressive chemicals, manufacturers can trust that their tools will maintain their integrity and performance.

The high compressive strength of cemented carbides is another factor that contributes to the reliability of carbide rotary tool bits and burr tools. These tools can withstand significant pressure without deformation, allowing for efficient cutting and shaping operations. This property is particularly important in applications where precision and accuracy are critical, as it ensures that the tools maintain their intended geometry during use.

In summary, the unique properties of cemented carbides make them indispensable in the manufacturing of carbide rotary tool bits and carbide burr tools. Their high hardness, wear resistance, thermal stability, compressive strength, and chemical stability contribute to the exceptional performance of these tools across various industries. As technology advances and industries continue to seek solutions that enhance productivity and efficiency, the importance of cemented carbides in tool manufacturing will only grow. These materials will remain at the forefront of innovation, enabling manufacturers to achieve their goals with reliability and precision.

Welcome to our grinding supplies company's website, where we proudly present our flagship product, the YG6X Carbide Rod....

See Details

Advantages: 1. Advanced Carbide Tips:- Precision Craftsmanship: The carbide tips featured in the MKW-10 Series Saw Blade...

See Details

Welcome to our MKW-14 Series Saw Blades product showcase! Crafted with precision engineering and top-quality materials, ...

See Details

Welcome to our product page featuring the B3 Type Convex Circular Arc Shaping Turning Tool. Designed to meet the needs o...

See Details

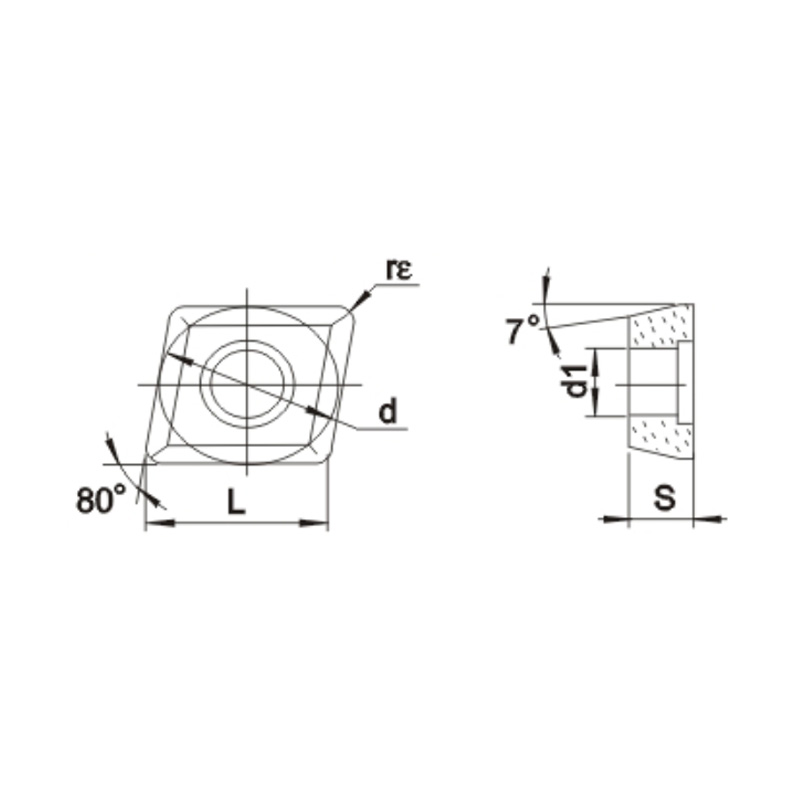

Welcome to our product page featuring the 95 Degree External Turning, Facing, and Boring Tools! Designed to meet the div...

See Details

Contact Us