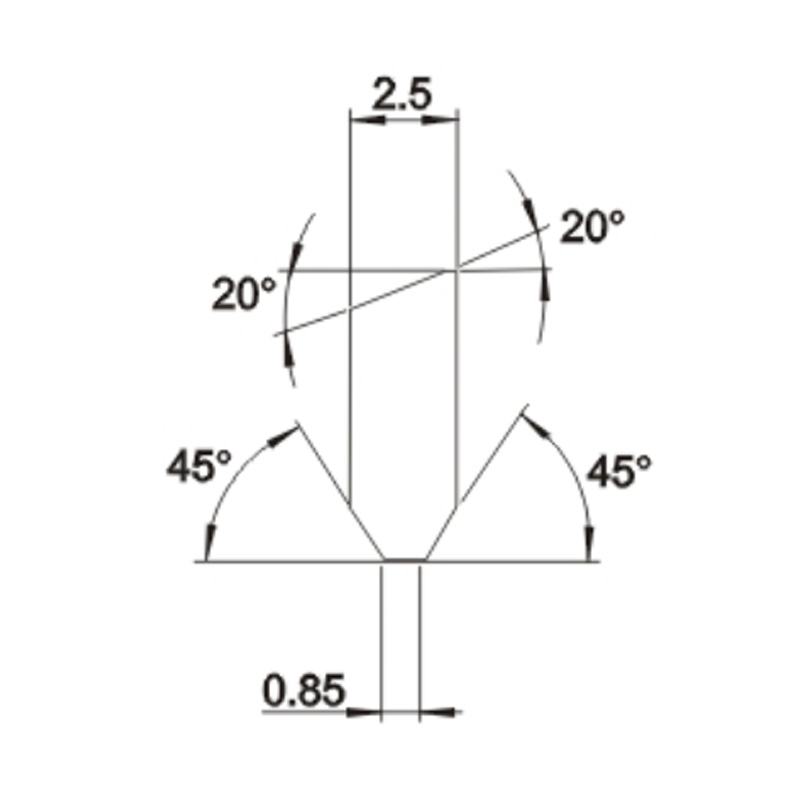

MKW-12 Series Saw Blades

Cat:Cemented Carbide Tips for Woodworking

Elevate your woodworking experience with our MKW-12 Series Saw Blades, meticulously crafted to meet the demands of high-...

See DetailsCarbide tip inserts and tungsten rotary burrs are essential tools in various industries, known for their durability and versatility. These tools play a critical role in shaping, cutting, and finishing materials across a wide range of applications. Understanding their uses and characteristics can provide valuable insights into their importance and benefits in manufacturing and machining processes.

Carbide Tip Inserts: Applications and Characteristics

Applications:

Carbide tip inserts are widely used in metalworking and machining operations. Their primary applications include:

1. Turning: Carbide tip inserts are commonly used in turning operations, where they help shape metal parts by removing material from a rotating workpiece. This process is crucial in producing cylindrical components with high precision.

2. Milling: In milling operations, carbide tip inserts are employed to remove material from a workpiece to create complex shapes and surfaces. They are especially useful in high-speed milling, where their hardness and heat resistance provide an advantage.

3. Drilling: Carbide tip inserts are also used in drilling operations, where they provide ideal cutting performance and extended tool life. They are suitable for drilling through hard materials, such as stainless steel and cast iron.

4. Grooving and Parting: These inserts are utilized in grooving and parting operations to create grooves or separate parts from a workpiece. Their precision and durability make them ideal for these tasks.

Characteristics:

1. Hardness: Carbide tip inserts are known for their exceptional hardness, which allows them to cut through tough materials with ease. This hardness also contributes to their wear resistance, ensuring a longer tool life.

2. Heat Resistance: The ability to withstand high temperatures without losing their cutting edge is a key characteristic of carbide tip inserts. This makes them suitable for high-speed machining, where heat generation is significant.

3. Versatility: Carbide tip inserts come in various shapes and sizes, making them versatile for different machining operations. Whether it's turning, milling, or drilling, there is a carbide tip insert designed for the task.

4. Precision: The precision of carbide tip inserts is unmatched, allowing for the creation of accurate and intricate parts. This precision is essential in industries such as aerospace and automotive, where tight tolerances are required.

Tungsten Rotary Burrs: Applications and Characteristics

Applications:

Tungsten rotary burrs are used in a variety of applications across different industries. Some of the common uses include:

1. Deburring: Tungsten rotary burrs are extensively used for deburring operations, where they remove sharp edges and excess material from workpieces. This process is crucial for ensuring the safety and functionality of machined parts.

2. Shaping and Sculpting: In metalworking, tungsten rotary burrs are employed to shape and sculpt metal components. They are particularly useful in creating detailed and intricate designs on workpieces.

3. Grinding and Polishing: These burrs are also used for grinding and polishing tasks, where they help achieve a smooth and finished surface on metal parts. Their ability to grind and polish hard materials makes them valuable in tool and die making.

4. Welding Preparation: Tungsten rotary burrs are used to prepare surfaces for welding by removing rust, scale, and other contaminants. This ensures a clean and strong weld joint.

Characteristics:

1. Durability: Tungsten rotary burrs are known for their durability and long-lasting performance. Their toughness allows them to withstand the rigors of heavy-duty applications.

2. Sharpness: The sharp cutting edges of tungsten rotary burrs enable efficient material removal, reducing the time and effort required for machining tasks. This sharpness also contributes to their precision in shaping and sculpting operations.

3. Heat Resistance: Similar to carbide tip inserts, tungsten rotary burrs exhibit ideal heat resistance. This characteristic ensures that they maintain their cutting performance even at high temperatures.

4. Versatility: Tungsten rotary burrs are available in various shapes and sizes, making them suitable for a wide range of applications. From deburring to polishing, they offer versatility in metalworking and machining processes.

Carbide tip inserts and tungsten rotary burrs are indispensable tools in the machining and metalworking industries. Their unique applications and characteristics make them valuable assets for achieving precision, efficiency, and durability in various operations. By understanding their uses and benefits, professionals can select the appropriate tools to enhance their machining processes and improve overall productivity.

Elevate your woodworking experience with our MKW-12 Series Saw Blades, meticulously crafted to meet the demands of high-...

See Details

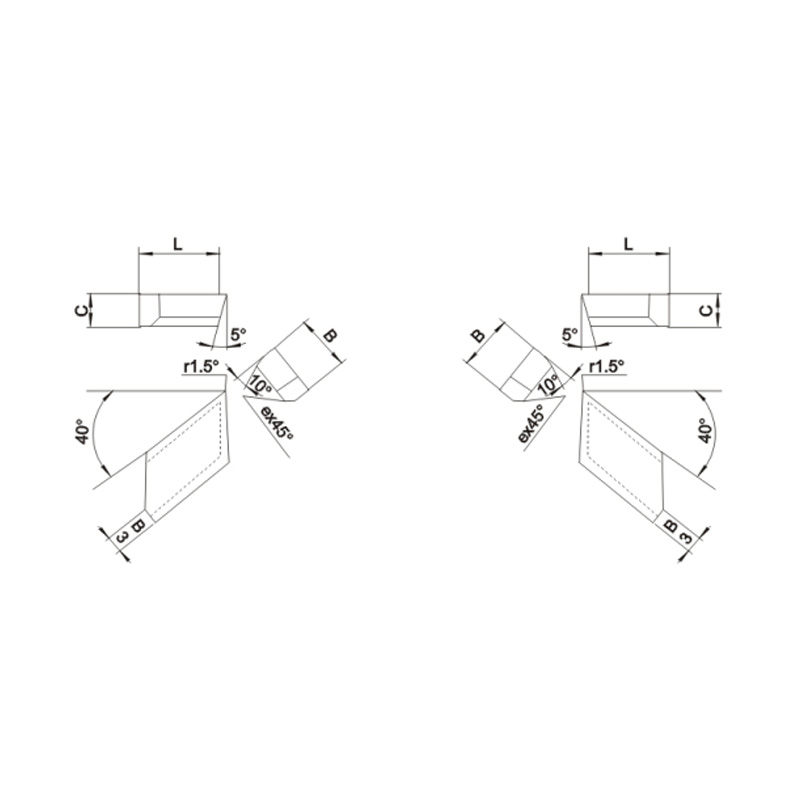

Welcome to our product page featuring the B1 Type shaping turning tool, dovetail groove cutter, and dovetail groove wond...

See Details

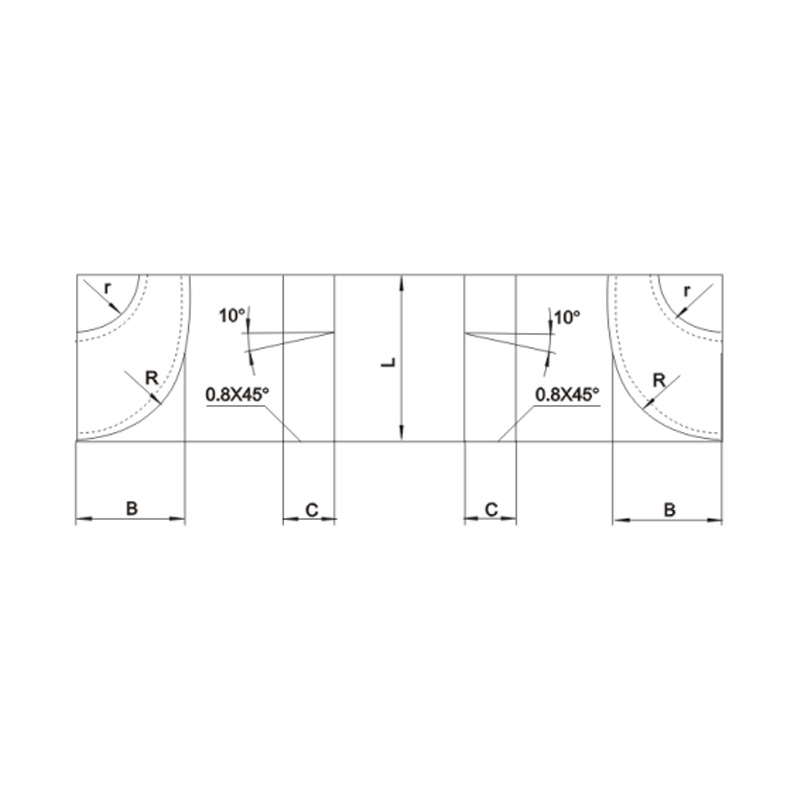

Welcome to our product page featuring the B3 Type Convex Circular Arc Shaping Turning Tool. Designed to meet the needs o...

See Details

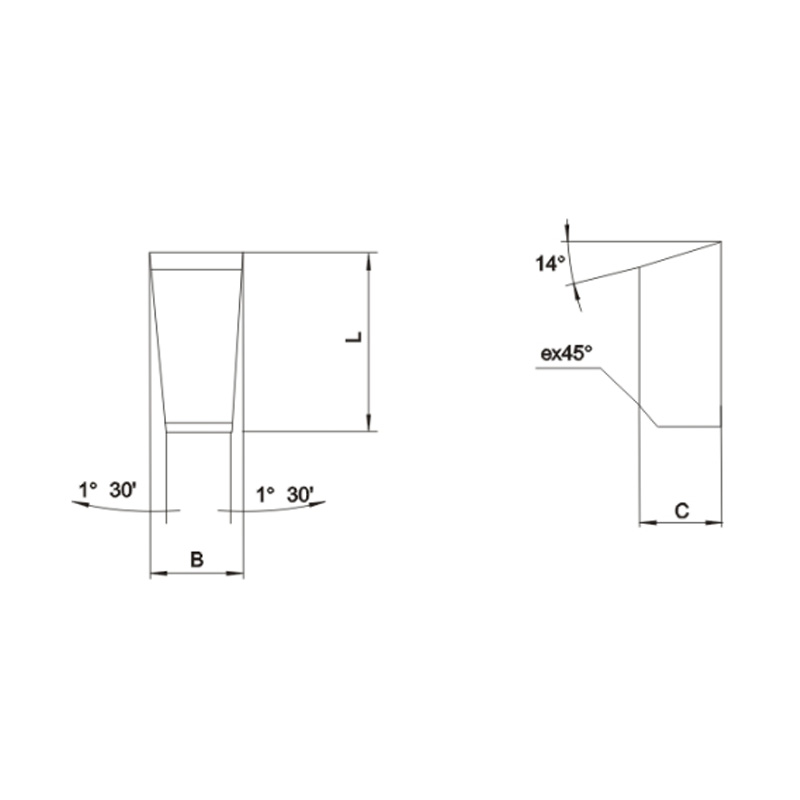

Welcome to our product page featuring the C3 Type for cutoff tool and grooving cutter! Our company specializes in provid...

See Details

Welcome to our product page featuring the Shallow Hole Drilling Cutter Blades! Designed specifically for shallow hole ma...

See Details

Contact Us