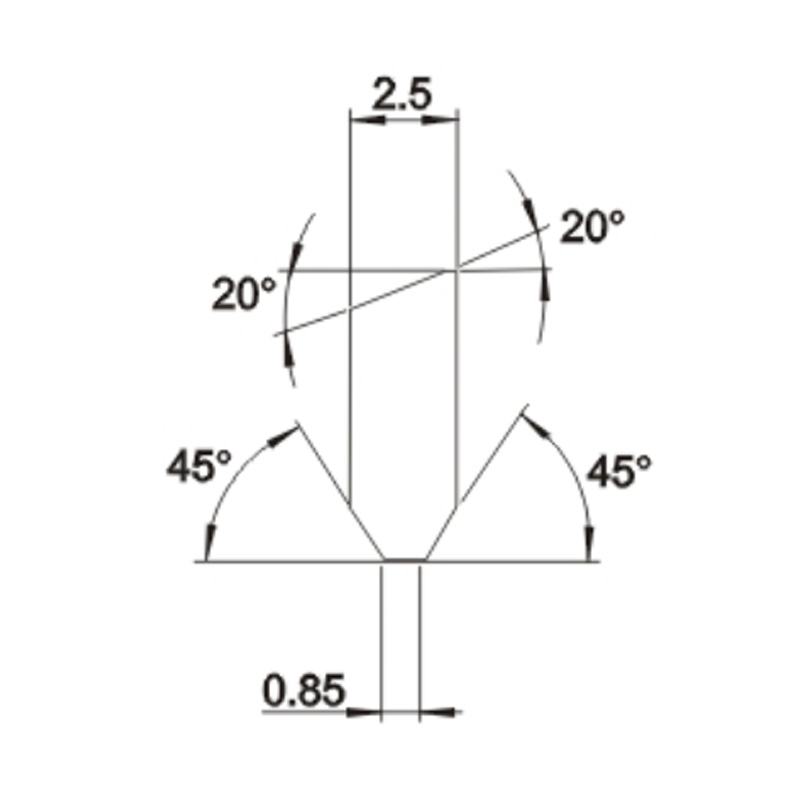

MKW-12 Series Saw Blades

Cat:Cemented Carbide Tips for Woodworking

Elevate your woodworking experience with our MKW-12 Series Saw Blades, meticulously crafted to meet the demands of high-...

See DetailsIn industrial production, the choice of materials directly affects product quality, production efficiency, and corporate economic benefits. With technological advancements and the continuous upgrading of manufacturing requirements, traditional metal materials have gradually exposed their limitations. Cemented carbide rod, as a high-performance material, is increasingly becoming the preferred choice in many fields. This article focuses on the significant advantages of using cemented carbide rod compared to traditional materials, particularly its longer lifespan and higher efficiency.

Longer Lifespan

Cemented carbide rod is a composite material made from tungsten carbide particles bonded with cobalt, nickel, or other metallic binders through a powder metallurgy process. This unique composition gives cemented carbide rod an extremely high hardness (typically HRA 86-93), far exceeding that of ordinary steels and other traditional materials. The high hardness means that cemented carbide rod has great wear resistance and corrosion resistance, maintaining good performance even under severe working conditions. Therefore, tools and components made from cemented carbide rod, such as drills, milling cutters, and punches, have lifespans several times to several dozen times longer than those made from traditional materials. For example, in metal cutting operations, tools made from cemented carbide rod can withstand the high temperatures and pressures generated by high-speed cutting while significantly reducing wear, thereby extending tool life and reducing production costs.

The extended lifespan of cemented carbide rod is not just a matter of durability; it also translates into significant cost savings. By reducing the frequency of tool replacements, companies can minimize downtime and maintenance costs, result in increased overall productivity. Additionally, the reliability of cemented carbide rod ensures consistent performance, which is crucial for maintaining high-quality standards in manufacturing processes.

Higher Efficiency

In addition to wear resistance, cemented carbide rod also exhibits great thermal stability. This means it can maintain stable physical properties at high temperatures without deforming or deteriorating. This characteristic makes cemented carbide rod ideal for applications requiring long periods of continuous operation, such as cutting tools on automated production lines. Since cemented carbide rod can achieve high-speed machining without sacrificing precision, it not only increases production efficiency but also reduces downtime, result in greater economic benefits for enterprises.

Furthermore, the high strength of cemented carbide rod allows for the design of lighter and more complex tool shapes, further optimizing the machining process and enhancing work efficiency. For instance, in the automotive industry, precision tools made from cemented carbide rod enable faster and more accurate machining of engine components, contributing to the overall improvement in vehicle performance and reliability.

Expanding Application Areas

As cemented carbide rod technology continues to mature, its application scope is expanding. Beyond traditional mechanical processing, cemented carbide rod is finding new applications in industries such as aerospace, automotive manufacturing, and medical equipment. For instance, in the aerospace industry, cemented carbide rod is widely used in the manufacture of aircraft engine components due to its great high-temperature resistance and lightweight characteristics. In the medical field, cemented carbide rod is an ideal material for surgical instruments because of its biocompatibility and non-magnetic properties.

The versatility of cemented carbide rod is further demonstrated in mining and oil drilling, where its exceptional wear resistance and durability make it suitable for harsh and abrasive environments. Tools and components made from cemented carbide rod can withstand the harsh conditions encountered in these industries, ensuring reliable and efficient operation.

Environmental and Economic Benefits

Using cemented carbide rod also brings environmental benefits. The reduced need for frequent tool replacements means less waste and lower resource consumption. Additionally, the longer lifespan and higher efficiency of cemented carbide rod contribute to energy savings, as fewer resources are required to maintain and replace tools. This aligns with growing global efforts to promote sustainable manufacturing practices and reduce the environmental impact of industrial activities.

Future Prospects

With ongoing advances in materials science and manufacturing technologies, the future of cemented carbide rod looks promising. Research and development efforts are focused on improving the material's properties, such as enhancing its toughness and reducing production costs. These innovations will likely expand the range of applications for cemented carbide rod and further solidify its position as a key material in modern industry.

In summary, cemented carbide rod's outstanding performance, longer lifespan, and higher efficiency make it a preferred choice in various industrial applications. Whether from an economic perspective or in terms of technological development, choosing cemented carbide rod is a wise decision. As new material technologies continue to evolve, we can confidently expect that cemented carbide rod will play an increasingly important role in driving industry forward.

Elevate your woodworking experience with our MKW-12 Series Saw Blades, meticulously crafted to meet the demands of high-...

See Details

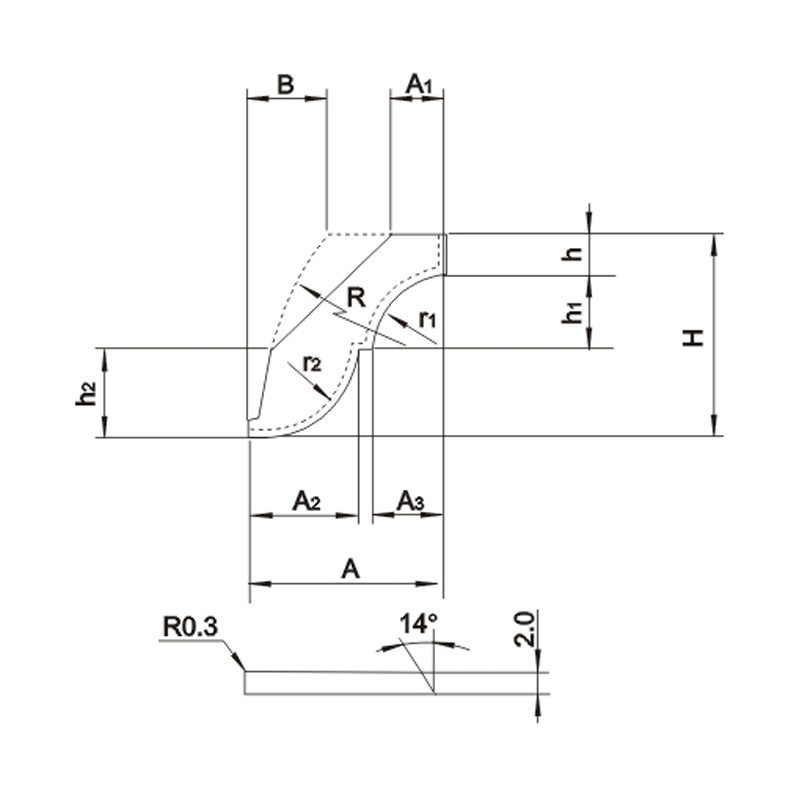

Welcome to our product showcase featuring the Double-Sided Door Panel Edge Profile Cutter Blade! Designed for precision ...

See Details

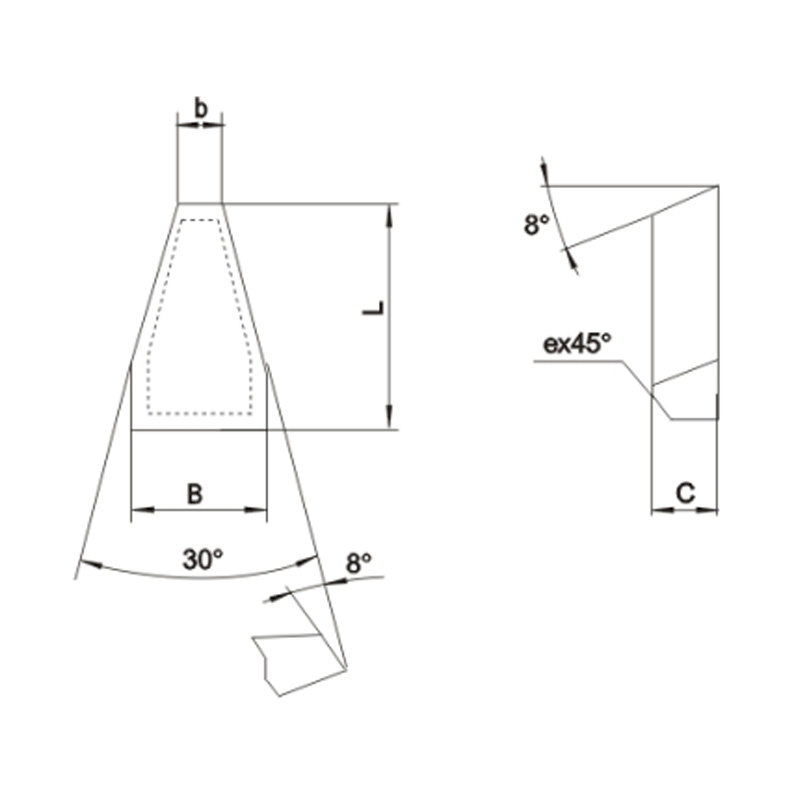

Welcome to our product description for the C2 Type turning tool, specially designed for refined turning and ladder screw...

See Details

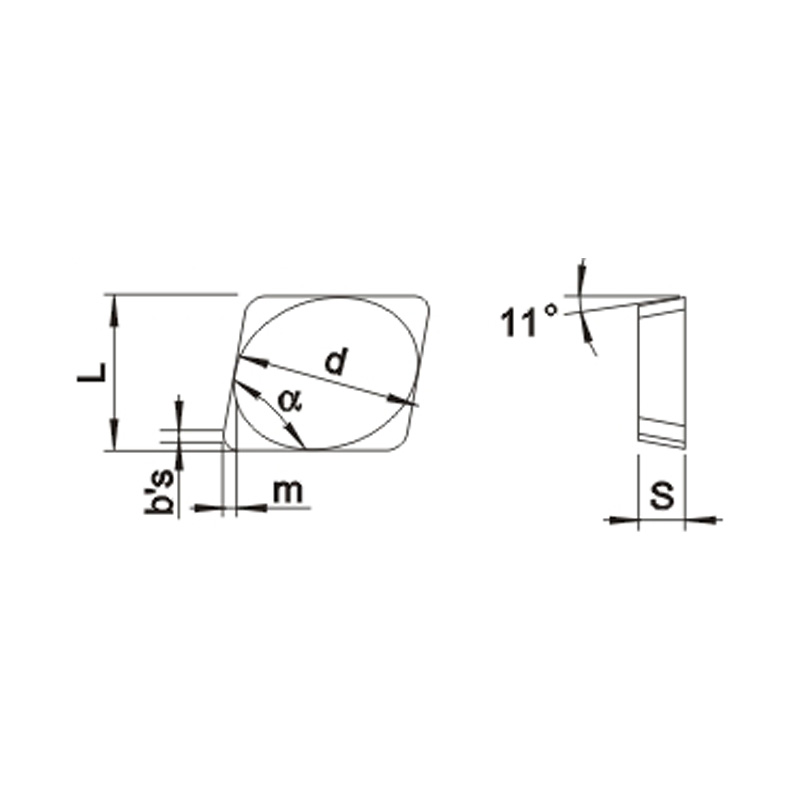

Welcome to our product page featuring Right Angle, Three-edge Milling Cutter Blades! These blades are meticulously desig...

See Details

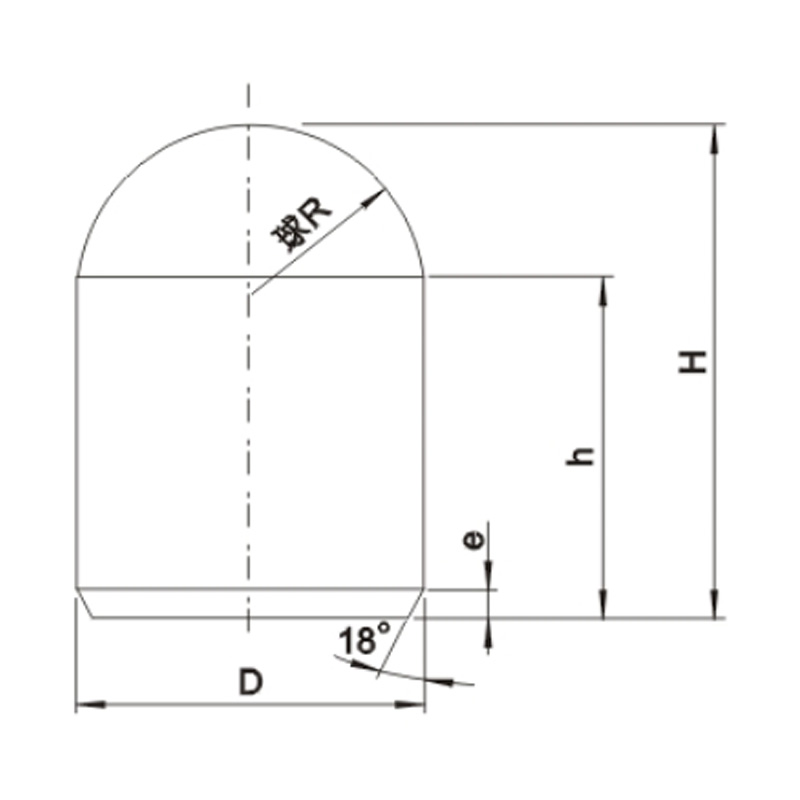

Welcome to our range of Carbide Inserts DQ Type (Q type spherical tooth), the pinnacle of durability and efficiency in d...

See Details

Contact Us